Additive Manufacturing Is Changing How We Design

Geometric freedom is just the start. AM will also change how design happens.

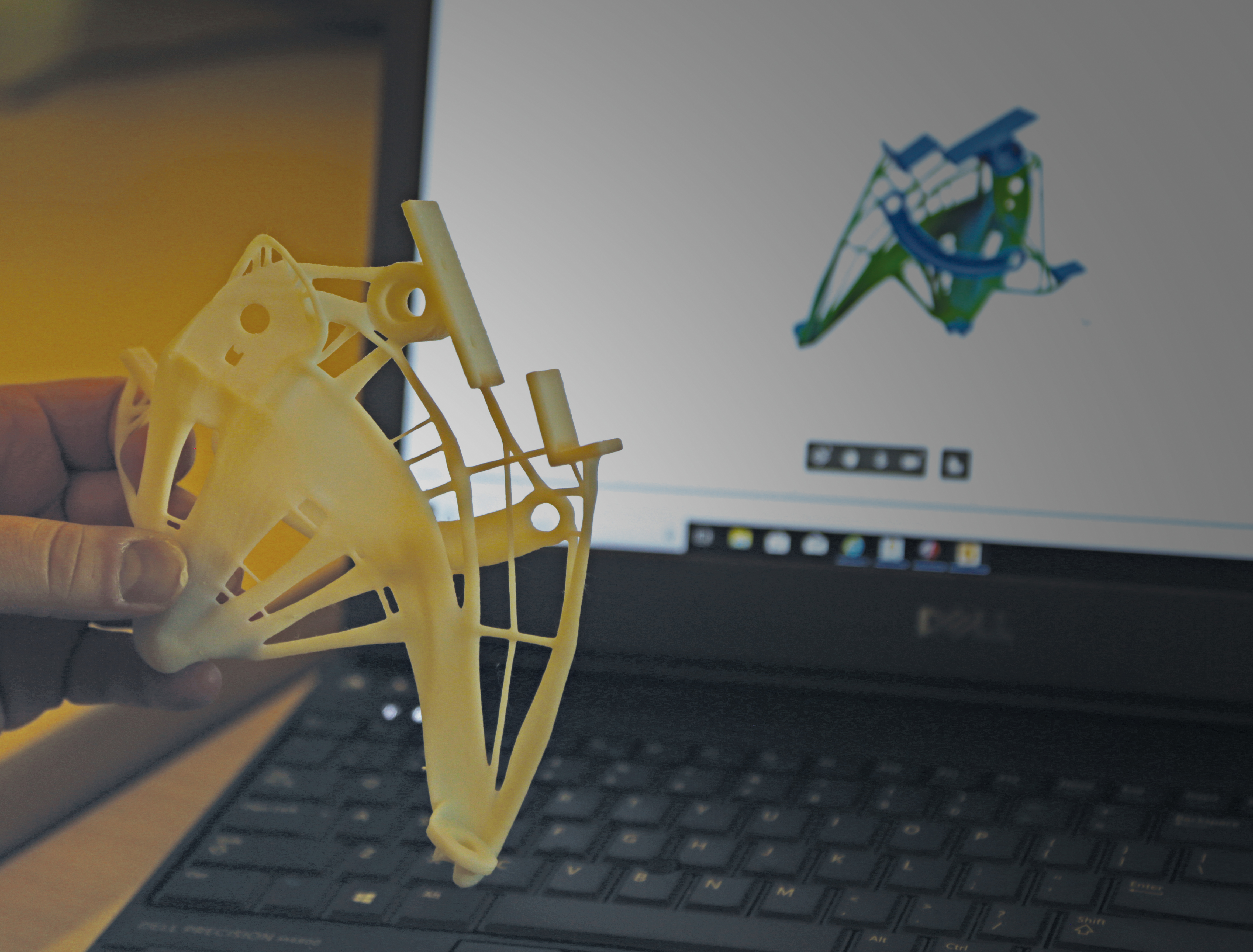

Additive manufacturing will change design. It won't just change design geometries, it will also change how design happens. Hear more in the video above and visit this content collection exploring the intersection of AM and design.

Transcript

Additive manufacturing will change design—not just design geometries, but how design happens.

We're accustomed to design and manufacturing being separate. You lock in the design then you tool up and produce. But with additive, there's no tooling and what used to be separate steps performed by separate suppliers could now all consolidate into one 3D printing build.

As a result, we're free to keep on refining the design. We're free to change the design in the midst of production if the market says that the details or a feature of a given product has to change, we can make that change in production and keep producing.

So when does prototyping end and production begin? And when is the design work really over? With additive, design and manufacturing blend together.

Design for Additive Manufacturing (DFAM)

Design for additive manufacturing (DFAM) goes beyond design for manufacturability. Generative design and topology optimization make it possible to design shapes that only 3D printing can make. VISIT THE ZONE

Related Content

-

NIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

-

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.