Video: Selective Laser Sintering for Production of Large Parts

SLS offers a production option enabling large, precise plastic parts to be made cost-effectively in quantities generally too low for injection molding.

A challenge of large, intricate plastic parts is that they have tended to demand large production quantities. Only large quantities can justify the mold tooling required. But Chuck Kennedy, VP of operations with additive manufacturing machine maker Farsoon, says advances in selective laser sintering (SLS) have made it competitive with injection molding in precision and quality. For large plastic parts such as the HVAC component seen on this page, 3D printing via SLS now offers a production option allowing the part to be made cost-competitively in quantities of 50,000 or less rather than the hundreds of thousands that the economics of injection molding would require. Kennedy and I recently talked about SLS as an alternative to molding for large parts.

Transcript

Peter Zelinski, Additive Manufacturing

Chuck, you brought in a really big part here. What is this?

Chuck Kennedy, Farsoon Technologies

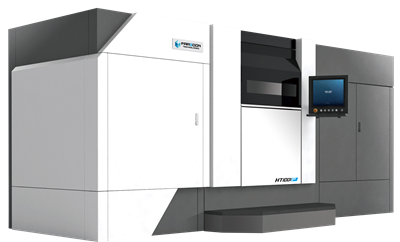

It's a selective laser sintering (SLS) part built in our new model HT1001P. This is our standard nylon PA12 material that we make at our factory as well, so we manufacture the material as well as the machines.

Peter Zelinski

This is an HVAC component.

Chuck Kennedy

Yes, it's a HVAC component for one of our partners in China but it's a global company and they just happen to be manufacturing the HVAC components there. It used to be that this was a molding application.

Peter Zelinski

It was formally injection molded in in all one piece like this.

Chuck Kennedy

No, it was probably about a two- or three-piece mold. They consolidated it through design.

You can see that there's a lot of hidden channels, undercuts, those type of things. All of those things require some level of tooling. They were able to simplify some of that design. Then, through additive, they're able to do this in one piece. This piece was done in about 10 hours.

Peter Zelinski

Do you know why the manufacturer arrived at 3D printing as the alternate process for this part? Was there a particular challenge with this component when it was molded or was it a particularly difficult part?

Chuck Kennedy

When you look at general tooling injection molding, you've got to amortize the cost of those tools over time. If you're looking at a tool that maybe costs $500,000 to do, you've got to amortize that over many components and it ends up being a million-component type of amortization. They may not have a car with that life cycle but they're going to sell that many units. That's how they derived that per piece aspect of the cost.

We've got a limited volume of these cars and we only need 50,000 of these parts over the next five years or three years. Do we want to spend this amount on tooling or produce the part in additive? [This] also allows them to come back into making slight design changes and they can make those changes on the fly and improve things.

Peter Zelinski

Those who are familiar with additive are not surprised by the complexity of this part. We're very familiar with seeing complex parts made additively, but we're not necessarily familiar with additive being made for a production part or part at this scale. Let's talk about the size first. Are there technology advances or improvements that have made it practical to do SLS for a part this big?

Chuck Kennedy

Yeah, it kind of starts with the scanners and the lasers. There are some technical advantages with scanning systems and selective laser sintering because of the accuracy of the galvo systems. It allows you to meet accuracies that you normally would only get out of injection molding. When you're talking about those levels and this is scalable to the point where we could add four lasers, eight lasers, eight scanners to really scale this up for larger production as well.

Peter Zelinski

You mentioned tens of thousands of units perhaps. What does the additive manufacturing system or platform look like that takes apart like this and repetitively produces at production scale?

Chuck Kennedy

Picture a conveyor belt system. This system alone has a pre-heat station. You have your cartridge in there that's been preheated. Then, you have your build station. After [that] finishes it moves over to an automated cooling station. Then, it allows the next chamber to come into the build station already preheated and then starts up your next build. It truly gets to that point where you're doing chain production.

Peter Zelinski

What is your sense of what that will mean? This is 3D printing as an alternative to injection molding. How far can 3D printing go as a production process for parts like this?

Chuck Kennedy

The big gap there is the raw material cost. Additive materials are still at a point where the per kilo price of powders is significantly higher than pellets, for instance. The initial phases are going to really be designed around custom, limited quantities. Picture some of the custom cars that are out there that they're only going to [make] 1,000 cars. When you talk about things like widgets or gears or those types of things, you take something that requires three or four parts to be screwed together. Now through additive you can do it in one part, and you can fit a thousand of them onto a build tray. There's your value in getting out of that injection molding side. But, big parts like this? It's going to be in the low volume, highly complex parts.

Related Content

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreWith Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreRead Next

Video: The Pella Corporation Is Succeeding With 3D-Printed Tooling

An engineering leader with the window and door maker shows examples of the tooling and machine parts now produced for the company's manufacturing processes using 3D printing.

Read MoreFarsoon Technologies’ Large-Volume Polymer 3D Printer Debuts in U.S.

The HT1001P, Farsoon's new large-volume polymer 3D printer, is set to be beta tested by two U.S. companies later this year. The system will eventually offer three tiers of automated production.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More