Combining different processing steps in one machine is attractive for several reasons: It saves space, may allow multiple materials to be combined in one workpiece and can enable a component to be machined in a single setup. Hybrid machines, where additive manufacturing processes are incorporated with machining, have been on the market for quite a while now, but a new system from Hermle promises to advance hybrid manufacturing of complex parts using multiple materials.

Berthold Hermle AG entered the field of additive manufacturing in 2013. Hermle Maschinenbau GmbH, a 100 percent subsidiary with headquarters in Ottobrunn near Munich, is offering the Metal Powder Application process (MPA), which is combined with five-axis machining in one machine. The company is using a hybrid machine, the MPA 40, which has a powder application nozzle mounted alongside the vertical milling spindle and a heater built into the fourth/fifth-axis rotary table. According to Franz-Xaver Bernhard, member of the board at Hermle AG in Gosheim, Germany, a new machine version, the MPA 42 is on its way to be implemented, with first prototype scheduled to be installed at the end of August.

The machines are not for sale, yet, but in addition to R&D, Hermle has production capacities for applications of the MPA technology to offer hybrid manufactured individual components to its customers. “The ultimate goal is to sell our hybrid machines, but we don’t know yet when we’ll be ready to do that,” says Bernhard. “The process is working really well and we are faced with more demand for hybrid parts than what we can deliver. But so far the process is so complicated and runs within fixed parameter settings for all the different materials, geometries, etc. which we have not been able to automate yet.”

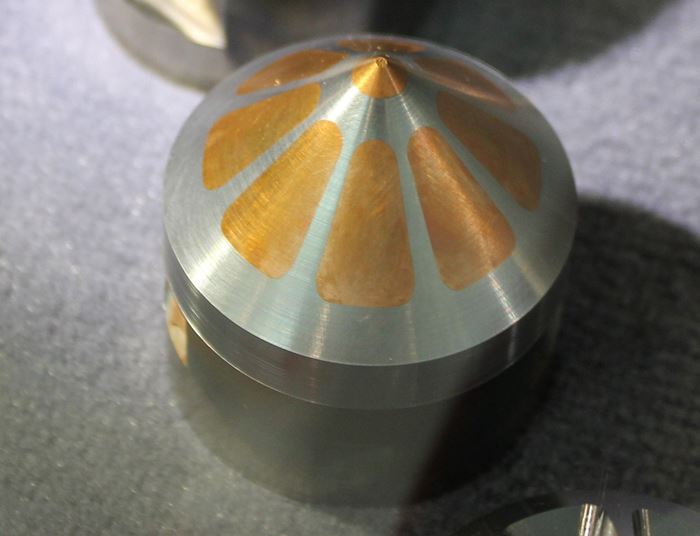

Metal powders (including hot/cold-working steels, stainless, invar pure iron, copper and bronze) are the base material for additive manufacturing with Hermle MPA technology. The physical properties of the applied metal layers and the transitions between materials must meet the high mechanical and thermal requirements defined by the operational environment of the manufactured component. Precise adjustment of the process parameters is therefore essential for each metal powder used. The properties of the resulting material microstructure are determined in extensive test series. In addition to tension and compression tests, information about particle and layer adhesion, porosity, and material inclusions is derived from the examination of grindings in an optical microscope.

“Our experts are able to use the machine with all necessary parameter settings, but we would have to sell them alongside the machine if we wanted to sell it at this point of time,” Berhnard says. “It is similar to EDM machines in the old days, where the operator was faced with hundreds of buttons to set up and adjust the process parameters.”

Micro-Forging to Build Completely Sealed Materials

MPA technology is a thermal spray process for metal powder. The material is applied by kinetic compacting—or micro-forging—in a process which uses metal powder, water, electricity and oxygen-reduced compressed air to build completely sealed materials. When depositing the material, powder particles with grain sizes of 25 to 75 microns are accelerated to very high speeds (as much as three times the speed of sound) by means of a carrier gas and applied to the substrate via a “de Laval” nozzle at temperatures ranging to 1,000°C. The heat, speeds and pressure of the method leads to strong deformation of individual particles and results in a binding contact surface between them.

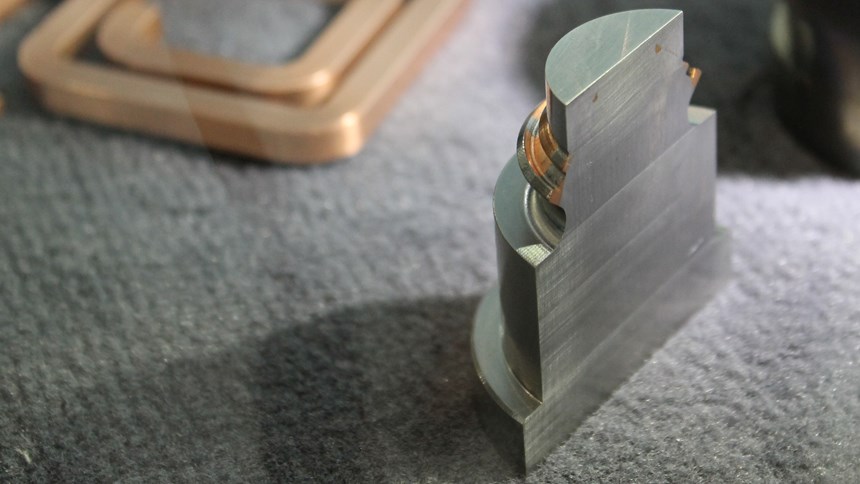

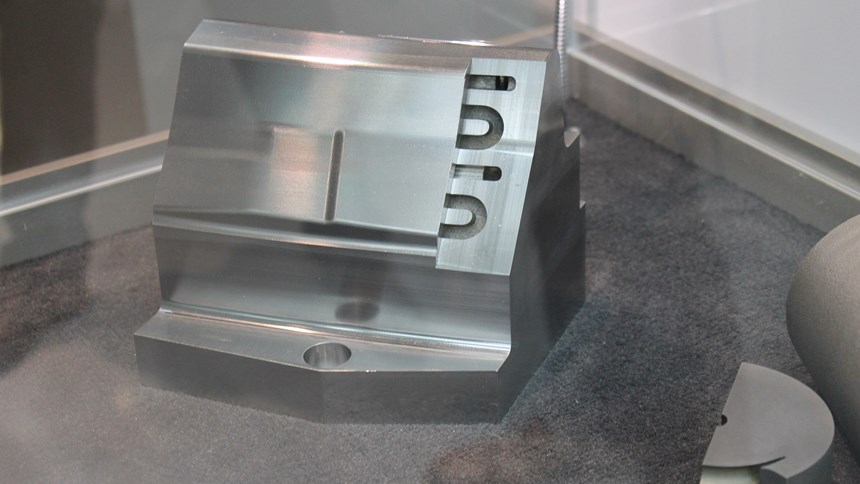

The material is deposited in layers until the contours of the component are accessible for milling. After machining the contours, the deposition process is repeated. Alternate deposition and removal is carried out on five axes using an in-house CAM development, Hermle‘s MPA Studio. Up to six powder conveyors can be controlled simultaneously, enabling functionally graded materials and material mixtures layering as many as six dissimilar metals. There are therefore no limits to the process in the metals sector, Hermle says.

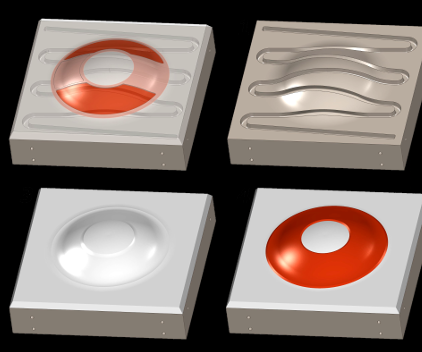

According to Hermle, the strength of the MPA technology lies in the deposition of large volumes on semi-finished products with free-form surfaces in combination with cavities such as cooling channels, internal cavities, undercut contours or integral heating wires, applications which cannot be covered by any other generative manufacturing process. A special filling material allows for the creation of inner hollow areas, channels and undercut contours. This material is water-soluble and flushed out at the end of the manufacturing process to expose the inner geometry. Subsequent heat treatment optimizes the component's microstructure and ensures the component has the desired hardness.

Dissimilar materials like a heat-conducting copper core inside a tool steel exterior can also be created. Workpiece dimensions of more than 0.5 × 0.5 m with total weights ranging to 600 kg can be created on the machine. Moreover, in contrast with deposition welding, in the MPA process the deposited powder is not fusion-bonded, which means that the resulting stresses in the component are very small.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreHow Electroplating Works for Polymer 3D Printed Parts

Baltimore-based RePliForm specializes in electroplating of 3D printed polymer parts for functional applications. This video explores how the process works, and potential benefits and uses for this technique.

Read MoreRead Next

Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreDesign Enhancements for Conformal-Cooled Insert Leverage 3D Printing Capabilities

A collaborative mold project reveals that the value of 3D printing isn’t in the process, it’s in the products.

Read MoreOvercoming the Challenges of Copper

A research organization in Germany is developing a laser beam source that operates with a green light, enabling selective laser melting of a copper alloy.

Read More

_wide.jpg;maxWidth=2000;quality=70)