PrintParts is a New York City-based service bureau with roughly 50 3D printers, including FFF, polymer SLS, SLA and DLP capabilities. Photo Credit: PrintParts

At the beginning of 2020, Robert Haleluk set an objective for his New York City-based service bureau, PrintParts. “My goal for that year was to find one customer that I could produce 100,000 pieces on one project for,” he says. “I wanted to check that box, and I wanted to prove additive can do that.” Within a few months, PrintParts would exceed this goal 20 times over while navigating a global health crisis.

This experience showed that additive manufacturing can succeed at production, but it also highlighted some of the new challenges AM introduces, including traceability and counterfeiting. Traceability solutions, such as the one developed in-house by PrintParts, can help negate these issues and provide new opportunities for collaboration throughout a part’s supply chain.

From Printing Parts to Prime Contractor

Haleluk was first introduced to 3D printing when working for his father’s manufacturing business, which included processes such as machining, injection molding and assembly. “As additive started to become a larger part of those discussions in those factories 10 years ago, I saw the opportunity to start using it,” he says. It was useful for tools and fixtures throughout the business, “But I saw the opportunity that as these machines got better, more efficient, cheaper, this is going to start to compete with the business that we’re molding parts for.”

In 2016 Haleluk started PrintParts, a New York City-based service bureau. The first machine was a MakerBot, but the company quickly expanded into Markforged FFF and Formlabs SLA machines. “My whole concept, coming out of a factory where I had machines the size of a school bus, was, why buy one when I could buy 10 or 20 and do it at scale?” he explains. “To me, the opportunity was always smaller machines, smaller footprint, but more of them.”

Today, the service bureau’s work is varied. “Most of our business is in production end use parts with tier one, tier two, tier three suppliers, whether that’s automakers or medical,” Haleluk says. “It kind of spans the whole gamut.” The facility currently has about 50 machines, including 30 Markforged, five Formlabs Fuse One polymer SLS machines, as well as Formlabs SLA machines and DLP machines from EnvisionTEC (later acquired by Desktop Metal and rebranded ETEC).

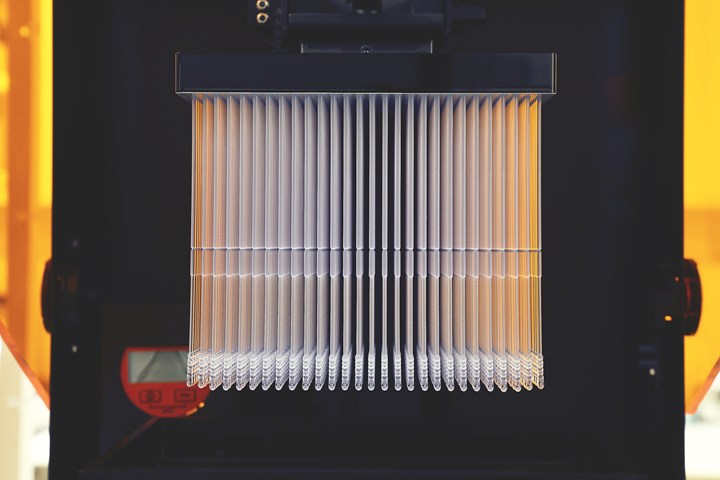

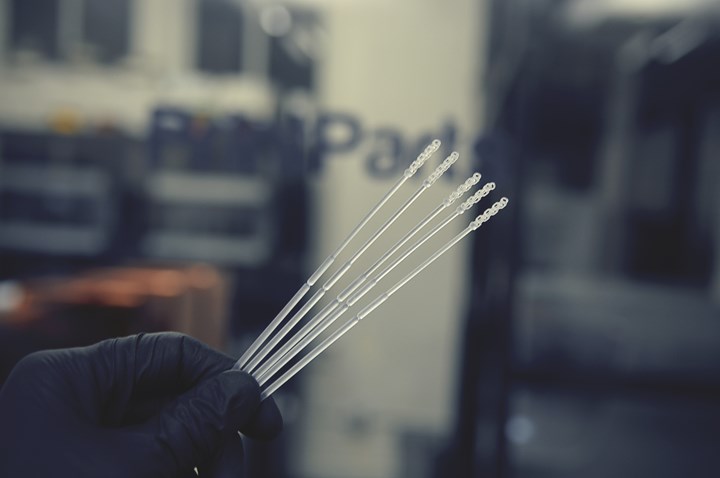

PrintParts became a prime contractor providing 3D printed nasopharyngeal swabs to New York City during the height of the COVID-19 pandemic. The company delivered more than 2 million swabs over nine months, all of which were printed on EnvisionTEC DLP machines. Photo Credit: PrintParts

PrintParts purchased the DLP machines in early 2020 for a very specific job — printing nasopharyngeal swabs during the COVID-19 pandemic. As PrintParts was looking for opportunities to use its 3D printing capacity to help out in some way at the beginning of the pandemic, there was a shortage of swabs needed for COVID testing. The PrintParts team members learned through their network that several 3D printer OEMs were developing and testing 3D printed swabs. While coordinating with city officials, they got into contact with these companies to evaluate the options. The company decided to go with EnvisionTEC, which was working with the Harvard and Beth Israel Deaconess Medical Center in Boston on swab development and approval, and purchased eight DLP machines specifically for swab production.

This led to a scramble for PrintParts to set up the machines for production. The company secured extra space in its building to house the machines, but finding shelves for them proved to be a struggle at the height of COVID lockdowns. IKEA was closed, so “I called up IKEA Sweden, and I got them to open a building in Connecticut because I told them the story,” Haleluk says.

Within 90 days of its first phone calls about the project, the swabs had been approved, PrintParts had set up production with help from a state grant and become the city’s prime contractor for swab production. “It was bonkers,” Haleluk says. “It doesn't even feel like it was real, because it was so fast.”

The company initially expected the job to last three months, but it ended up being a nine-month project. In that time period, PrintParts set up a supply chain that included two other service bureaus, along with companies downstream for sterilizing, kitting and delivering the swabs. Over the course of those nine months, this supply chain delivered more than 2 million swabs to New York City and other sources.

These 2 million swabs were printed in batches of 400 (410 fit on every build plate, but 10 were held back for quality control per FDA regulations) every four hours. Haleluk says that DLP turned out to be an ideal process for this job, because its ability to cure an entire layer at one time (instead of going point-by-point with a laser) helped increase throughput. After printing, the swabs went through postprocessing steps, including rinsing and curing in a specially built curing chamber (standard models were too small for the service bureau’s output).

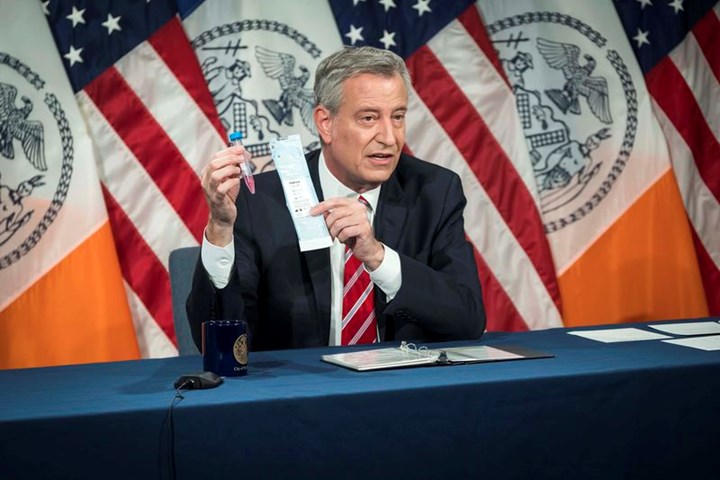

Then-New York City Mayor Bill de Blasio announced PrintParts as the supplier on record for 3D printed nasopharyngeal swabs during a televised press conference. Photo Credit: PrintParts

Looking back on the experience, Haleluk says that it proved to him the potential of additive manufacturing. “To me, it was getting back to the ethos of why I started this business,” he explains. But at the same time, it brought attention to some potential problems that AM introduces.

Counterfeiting and Traceability

One of these issues is counterfeiting. Anti-counterfeiting measures that have worked for other production processes aren’t as applicable with 3D printing. For example, before 3D printing, it was difficult to counterfeit an injection molded part without mold tooling. But now, anyone can theoretically scan a part and 3D print a counterfeit version. The digital files that are used for 3D printed parts can also be difficult to protect, which is another opportunity for counterfeiters. Counterfeiting is prevalent in aerospace, automotive and medical device industries. For instance, the 3D printed nasopharyngeal swabs that PrintParts was producing could have been counterfeited (and the PrintParts team suspects that counterfeit nasal swabs were floating around).

3D printing is also a more digital form of production, meaning it requires less human involvement in the supply chain. “It’s a benefit to speed and production on demand and sometimes cost,” Haleluk explains. “But it's also a little bit of a threat to quality control.” Without human engagement, traceability can be more difficult. “We learned very quickly that it's hard for us managing these machines just to even know some of those pieces of information,” he adds. “And it’s got to be harder at a larger scale when you think about production.” Injection molders can add markers to their tooling so customers can track which supplier, tool, purchase order and cavity a part came from in case there are issues. “Additive doesn't do that,” he points out. “And to do that with additive, you have to add steps in the manufacturing process.” This means either creating a new STL file for every part with that information, or adding a step in postprocessing.

The experience of producing swabs highlighted some of the challenges brought by 3D printing, including counterfeiting and process control. Photo Credit: PrintParts

PrintParts experienced these issues first-hand with the swabs as well. “We mixed up paperwork a couple of times. We were like, stop everything. We have to pull these swabs off the line because we couldn’t necessarily trust a traveler. It sucks, 400 swabs going in the garbage, but we can’t let that pass,” Haleluk says. “We didn’t put a date on a piece of paper or something got mixed up. It happens, right?” The situation highlighted the importance of traceability for the service bureau. “We lived this, and we understand the importance of traceability,” he explains. The company is using this as motivation to grow the other side of its business, SmartParts.

Making Parts Smarter

SmartParts offers a traceability solution that uses “programmable particles” made from ceramic-like rare earth elements. The particles act like bar codes — they’re assigned an optical conversion that can be read with an infrared (IR) scanner. The particles have a unique ID that, when scanned, references a database in the cloud holding relevant information about the material or the part. But while bar codes, like other traditional traceability solutions, are only relevant from the point they’re applied, these particles can be added to a material before it’s transformed into a part, giving true end-to-end traceability, starting from raw material.

The particles are flexible enough to work with a range of materials. “The reason we call it a programmable particle is because we can change the size, we can change the chemistry, we can change the composition, we can change the shape,” Haleluk explains. “And where one particle might work really, really well for spreadability in say, a metal powder or nylon powder for SLS or metal jet, it might be too dense or too heavy, or have the wrong characteristics to stay suspended in resin.” So far, the company has tested the particles in resin for injection molding and vat polymerization, powder for selective laser sintering (the ceramic-like particles can withstand the laser sintering process), and filament for extrusion-based processes. SmartParts is also working with partners to test powder bed fusion for metal AM, and is starting to have conversations about binder jetting.

Beyond adding the particles directly to raw material, they could also be added to materials for other processes like injection molding, or applied to parts via a paint, dye or coating. Although the particle quantity within the material is below contamination level (it’s measured in parts per million), there are still scenarios, including heavily regulated industries such as aerospace, where the material can’t have any additives. In these situations, users can incorporate the particles via a coating after they’ve been produced. “Additive is kind of our beachhead. That’s what we like to call it because it was the opportunity space,” Haleluk explains. “But it works just as well in traditional manufacturing. The delivery mechanism’s a little bit different.”

PrintParts developed an in-house solution for traceability called SmartParts. The technology consists of “programmable particles” assigned a unique ID that, when scanned, references a database in the cloud with information about the material or the part. Photo Credit: PrintParts

Tracing a Part

The particles are beneficial for a number of use cases, including anti-counterfeiting, lot-level traceability and confirming source of origin for materials. Haleluk says the latter is becoming a trend, especially with more companies being committed to environmental, social and governance (ESG), as well as sustainability. The particles could contain information on where a material originated, such as whether it was mined sustainably or comes from a specific approved source. This level of traceability could also help prevent liability issues, particularly for large suppliers in industries such as automotive. Right now, if there’s any question as to whether parts were made from the wrong materials, they need to be scrapped. “We can tag each of those materials, and you'll know exactly which material they are,” he says. “And if they ever start to blend together, our scanners can read that blend.” In any situation where material composition is in question, suppliers will easily be able to determine whether the parts are usable or scrap.

SmartParts are also useful for passing along information to the rest of a part’s supply chain, as well as end users. “We get to enable each one of those checkpoints along the supply chain, and each one gets their own value proposition,” Haleluk notes. “But as a greater goal, whoever's using these parts can look at that traceability, the history of that part from raw material through assembly and out the door.” For example, PrintParts has applied the particles to some parts for customers who are dual sourcing. This allows them to verify which parts came from PrintParts in case there’s an issue with parts from one supplier.

Eventually, scanning capability could be integrated into the 3D printer, enabling it to confirm the material before it starts printing. This would give manufacturers reassurance that they’re using the correct material for a job. Haleluk recalls a PrintParts job that required flame retardant material, and while the packaging said it was flame retardant, the spool wasn’t labeled as flame retardant. “What if the machine could catch that for me and prevent the human error that happened there?” he says. PrintParts sent that spool of material back to the supplier, but SmartParts technology would have enabled the company to confirm whether the material was correct or not. Printer OEMs can also use this data to see which materials customers are using in their machines, and shut the machine down if the material is incompatible, or make the user sign a waiver if the material isn’t approved. This creates a better experience for everyone in the supply chain. “If the OEM takes a license and he builds it into his materials set, and works with an OEM at the machine level to build a technology to read that material, you’ve created a better experience between both,” he says. They can hold each other accountable and sell a better product, because the buyer of the machine now can actually trace and prove that that material is what it's supposed to be.”

The programmable particles can be used for anti-counterfeiting, lot-level traceability and confirming source of origin for materials. PrintParts has also added them to parts for customers who are dual-sourcing, enabling them to verify parts from PrintParts in case of an issue with parts from one supplier. Photo Credit: PrintParts

The advance of 3D printing technology will also create new uses for SmartParts. “There’s going to be an opportunity one day to put particles exactly where you want them,” Haleluk says. Right now, particle dispersion is based on natural randomization, creating unique “fingerprints” within every part. But if the particles could be placed in precise locations, users could create shapes or designs within the part. When the whole part is scanned, the particles would create a point cloud, which could take the form of a watermark or barcode. “We’re still a little bit early, but it’s the right kind of early,” he notes. “Now we're entering the market where these machines are on the horizon.”

Integration and Partnerships

Right now, the company is considering different opportunities for SmartParts technology. “Our approach has always been around integration and partnerships,” Haleluk explains. This could take the form of licensing the technology or giving other companies access to it, licensing specific particle IDs to companies (like barcodes), selling particles as an additive that can be mixed into materials or coatings, or a pay-per-scan model.

Another avenue the company is exploring came as a result of the company’s participation in Hexagon’s Sixth Sense startup accelerator contest (which it won). Throughout Hexagon’s evaluation process, SmartParts was exploring what it would be like to integrate its technology with Hexagon’s Material Center platform for material lifecycle management. This is just one possible software integration for SmartParts. “If you think about the manufacturing execution side of it, you have a bunch of software companies that track digital very well. But they stop pretty much at point of print,” he points out. “They don’t go into the physical space.” By integrating SmartParts into MES, users can track a part throughout its physical journey.

Whichever path or paths SmartParts takes, it will remain flexible. “We want parts to become smarter. We want humans to do better,” Haleluk says. “We understand in order to do that, it’s not necessarily one pricing model. It’s not one business model.”

Related Content

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreRead Next

Is a Functional 3D Printer Network Possible? Automation Alley’s Project DIAMOnD and the Industry 4.0 Future

The initiative that placed 3D printers at more than 300 Michigan manufacturers is laying the groundwork for a future in manufacturing that is digital, distributed and largely additive.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More