Michigan-based nonprofit Automation Alley has a mission: to bring manufacturing into its Industry 4.0 future. Since its origins in 1999, the organization which first operated inside a single county has grown to serve manufacturers throughout the state, the country and now, the world. Its mission is to help these companies navigate disruption and implement emerging technology, ultimately embracing the principles of Industry 4.0 — in other words, manufacturing that is “software-driven, primarily additive and distributed,” says Pavan Muzumdar, chief operating officer.

Pavan Muzumdar, Automation Alley’s COO, processes 3D printed parts destined for Ukraine. These items — components for medical tourniquets — were printed on hundreds of different Markforged machines as part of the Project DIAMOnD network. Photo Credit: Automation Alley

The nonprofit has been working toward these objectives for years through various programs and partnerships, but the COVID-19 pandemic led to an initiative that has been a compelling test of its principles: Project DIAMOnD, standing for Distributed, Independent and Agile Manufacturing On Demand.

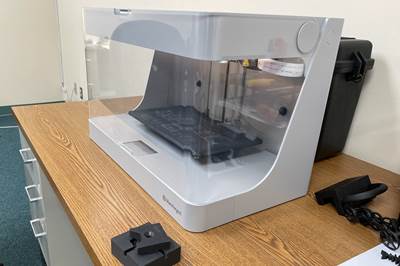

The federally funded project placed desktop 3D printers at more than 300 manufacturing companies throughout Macomb and Oakland counties in Michigan. While manufacturers are free to use these printers to support their own operations, the installation came with this caveat: Each of these printers is networked to the others, and can be controlled by a Command Center to be activated in case of future emergencies. The 3D printer network has been activated once already; lessons learned from that instance plus the experience of project participants are informing Automation Alley and its vision of the manufacturing future.

Double-Down on 3D Printing

Project DIAMOnD originated when Oakland County, seeking causes to support with federal CARES (Coronavirus Aid Relief And Economic Security) Act funding, encouraged Automation Alley to come up with an idea that would be both useful and transformative to the area’s manufacturers. On a very short timeline, Automation Alley conceived of and began to execute Project DIAMOnD, bringing on Markforged as the equipment provider and supporter, soliciting participant applications, and handling logistics to make the project happen. The first conversations about the initiative began circa June 2020, and by the end of December, printers were already in the hands of many of the network nodes. A representative from every node completed five days of training with Markforged, but then companies were free to experiment with their printers.

“We were inspired by what had happened in the Second World War, when the manufacturing community rallied to produce equipment for the war effort,” Muzumdar says. “We said, hey, let’s lean back on our belief that 3D printing is going to be the future and double-down on that. Let’s give manufacturers a 3D printer. Let’s teach them how to use it, give them some ideas, and then get out of the way.”

The model is proving to be astoundingly effective. Access to an industrial-level but still easy-to-use 3D printer has made it possible for companies to experiment with this technology in a low-risk way, without having to purchase the machines themselves. But there’s more to Project DIAMOnD participation than a free printer; the training and support provided by Markforged, Automation Alley and all the other nodes on the network function as a safety net for participants, a place to go for help. For the first 16 months or so, 3D printing had a chance to take root and spread. Some node companies applied their printers to prototyping, others to manufacturing aids, and some to entirely new product lines.

“A lot of companies have gone ahead and actually built business models around the printers,” Muzumdar says.

Responding to Conflict in Ukraine

But beyond encouraging additive manufacturing adoption, the other aim for Project DIAMOnD is to see whether a network of disparate 3D printers can actually work together in the case of an emergency. In April of 2022, the Command Center was activated for the first time to produce tourniquet parts destined for Ukraine. Across Macomb and Oakland counties, hundreds of 3D printers began printing first tourniquet clips and then handles. Automation Alley coordinated the collection, inspection and postprocessing as necessary for these parts, before they were shipped to Denmark for assembly and on to Ukraine.

“We wanted to see what it would feel like to actually do distributed manufacturing,” Muzumdar says. “It was a great opportunity to validate this, and it's going to save lives.”

The Ukraine project proved that such a network of coordinated printers can work in an emergency, and also taught Automation Alley a few valuable lessons. While the organization took on the responsibility of inspecting, cleaning and ensuring that support structures were removed from all the parts for Ukraine, this model likely isn’t sustainable; next time, Automation Alley plans to clarify who is responsible for which steps in the workflow and get other partners involved to oversee some of these tasks. Some 3D printers failed to produce parts that met the strength requirements for this application, so ensuring identical parameters is another point to improve.

These 3D printed tourniquet clips were produced during the Command Center activation for Ukraine. Each network node received a protected design file (to prevent changes) that their printers began to produce after finishing any existing jobs in the queue. Distributing production of these fairly simple parts across a network of mostly identical printers proved largely successful as a test of the Project DIAMOnD mission. More on 3D printing for Ukraine in this episode of the AM Radio podcast. Photo Credit: Automation Alley

Building the Language for Distributed Manufacturing

Over time the organization will work to make the 3D printer network as seamless, efficient and automated as possible. These efforts are not just about improving Project DIAMOnD, however, but also proving out a functional network for distributed manufacturing. According to Muzumdar, Automation Alley sees four enablers for distributed manufacturing:

- Digital rights management frameworks, which will be needed to distribute IP while maintaining rights;

- Digital identity frameworks, to validate users and ensure trust;

- Quality control including verification and traceability; and

- Universal product recipes that produce consistent parts when the right printer, material and settings are used.

Project DIAMOnD is the proving ground for these enablers right now, but its ongoing use and success could be a model for any future distributed manufacturing network.

“What we are building is a language that everyone agrees to speak and write and read,” Muzumdar says. Establishing that common tongue is key to making manufacturing anywhere across a network possible.

“...anyone can conceive of something of value.”

And that language could extend beyond manufacturers and OEMs. Ultimately Muzumdar could see another "D" added to beginning of the Project DIAMOnD moniker: Democratic. He has seen how 3D printing plays out at various nodes on the existing network; the machines' first users and beneficiaries tend to be the engineers, the people tasked with running and maintaining the machine.

“But within 60 to 90 days, it was the frontline workers who were coming up with the suggestions,” Muzumdar says. "And that’s the cool thing — anyone can conceive of something of value.”

The Project DIAMOnD printers have increased 3D printer availability and adoption such that many of these ideas can now take physical shape in Michigan manufacturing facilities. But more broadly, Muzumdar sees a future where distributed manufacturing means that anyone, anywhere could have access to production technology, regardless of skill or intended scale.

“We can make this accessible to anybody," he says. "You don’t necessarily need to have an engineering degree, and creators don’t have to strive to be the next Amazon to compete and participate.”

Related Content

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreRead Next

Status Check: Repeatable and Distributed Manufacturing in AM — Ready Yet?

With potential drift and IP barriers, is metal additive manufacturing ready to contribute to distributed manufacturing?

Read MoreMarkforged’s Eiger Fleet Enables More Control, Automation of Distributed Manufacturing

Cloud-based software solution manages distributed manufacturing operations on an enterprise and global scale with increased efficiency and insight.

Read MoreAdditive Manufacturing and the War in Ukraine: AM Radio #19

In this latest episode of the AM Radio podcast, we dive into the ways that AM is providing aid and also being affected by the conflict in Ukraine.

Read More

.jpg;width=70;height=70;mode=crop)