Software Streamlines Metal Additive Manufacturing Workflows

Replacing three software packages with 3DXpert from 3D Systems reduced one company’s file processing time and increased its productivity.

Using multiple software programs to design and produce 3D-printed parts can mean longer processing and manufacturing time and increased risk of errors in data transfer. With the help of an all-in-one metal AM software platform to optimize and prepare files for printing, a company accelerated file processing time as much as 75 percent and reduced manufacturing time as much as 40 percent.

Albany, Oregon-based Metal Technology (MTI) has more than 40 years of experience in a range of metal manufacturing capabilities, including deep-draw forming, forging, spinning and CNC machining. The company serves customers in aerospace, defense, nuclear and medical applications, managing complex designs and the requirements of working with specialized materials such as nickel superalloys, tantalum and titanium.

In an effort to reshape how it makes metal parts, the company expanded its capabilities to include AM. “We look at additive manufacturing, in this case direct metal printing (DMP), as a strategic capability that gives us the opportunity to develop parts with added functionality together with our customers,” Jason Stitzel, director of engineering, explains. CEO Gary Cosmer says its two 3D printers, a ProX DMP 320 and ProX DMP 200 from 3D Systems, “enable us to include features and design parameters that could not be done with traditional methods.”

Keeping its 3D printers running is critical to MTI’s business. “When our machine is sitting idle because it doesn’t have a build file to run, we’re losing money,” Stitzel says. This means that the printers need files to run, a process that required multiple software programs to convert a CAD model into an STL file, slice it into layers and create a build file. Transferring files to different programs often introduced errors, and a change in the model meant starting over from scratch.

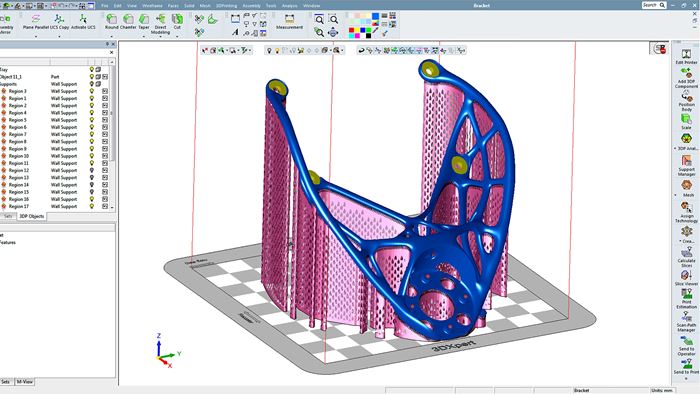

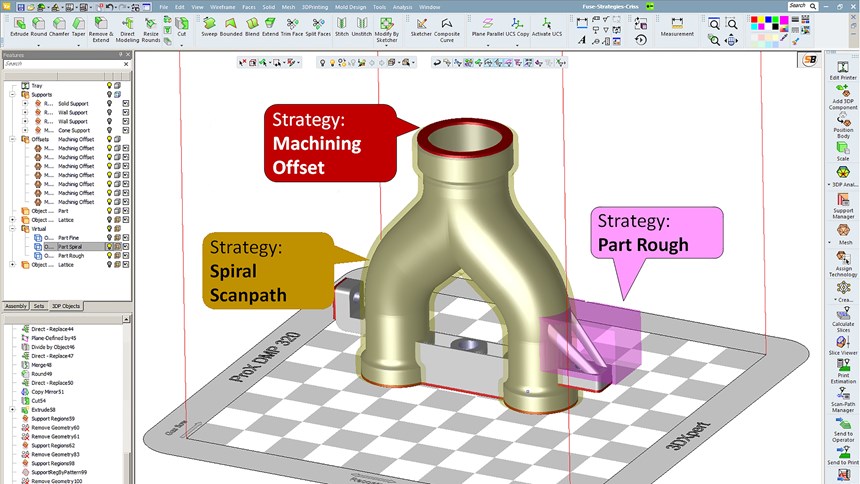

MTI chose to integrate 3DXpert from 3D Systems to minimize file processing time and streamline DMP workflows. 3DXpert is a design and manufacturing software platform for direct metal 3D printers. It includes ability to import part data, optimize geometry and lattice creation, set printing strategies, calculate the scan path, arrange the build platform, send it to the printer, machine the part, and perform post-printing operations. It works seamlessly with boundary representation and mesh triangulation formats, eliminating the need to convert solid or surface data into mesh for improved data quality, time savings and improved flexibility.

“Now we can receive files on a Friday and get them started over the weekend rather than delay to the following week.”

By including the tools needed to produce geometries and files that the printers can understand and use in production, the new solution reduced the number of software systems the company used from three to one. “It removes the need to convert from a solid model to an STL, a process that inherently introduces issues and errors,” Stitzel says. “Instead, we just pull the native CAD model directly into 3DXpert, modify it with CAD tools if we need to and apply the support structures.”

3DXpert can also reduce file processing time by as much as 75 percent, according to 3D Systems. For MTI, the time to process, slice, run parameters and create a build file for a complex part was reduced from close to 20 hours to four. “Now we can receive files on a Friday and get them started over the weekend rather than delay to the following week,” Stitzel says. “With our previous workflow, that just couldn’t happen.” He adds that the software is also more tolerant to design and orientation modifications, which is especially helpful in situations where parts are mission-critical and require expensive material. MTI wants to get the part right the first time, but often finds improvements later in the process. “In the past, any changes to the model meant we had to start over from scratch,” he says. The new software gives users the ability to make changes to parts without too much delay or cost overrun.

Beyond the efficiency of working with a single package, the software’s 3D zoning capability has enabled MTI to increase productivity by 40 percent. This capability enables users to define different printing strategies for different areas. “We can build a very thin shell that has a fine 30-micron layer to give us a really good surface finish, and then we can build the rest of the part that doesn’t require that level of finish in 60-micron or 90-micron layers and achieve almost identical mechanical properties,” Stitzel explains. He says that this is easier to achieve using 3DXpert than it is with other software, and helps the company better analyze and plan the part so it can use less support and material to further reduce cost and time.

Stitzel says that the software has been a big part of MTI’s successful use of 3D printing. “As we look forward, we know we can turn to 3D Systems for additional solutions such as inspection and post-printing operations that will make for a complete one-stop production solution,” he adds.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreCarnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

Read MoreUser-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.

Read MoreOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More