Applying “local” changes between the layers of a 3D printed part can have an impact on its “global” properties says Dr. Mike Sealy. At the University of Nebraska-Lincoln, he is leading research to apply this “glocal” mindset with hybrid manufacturing. Photo credits: University of Nebraska-Lincoln

The term “glocal” comes from the business world, but for Dr. Michael Sealy, the word is an apt descriptor for the hybrid manufacturing technique he is currently developing at the University of Nebraska-Lincoln. His research explores the potential for producing magnesium medical implants through a combination of metal 3D printing and laser peening, a mechanical hammering process typically used to finish part surfaces. Applying this secondary process strategically between layers of material during 3D printing, however, can have beneficial effects on the mechanical properties of the final implant.

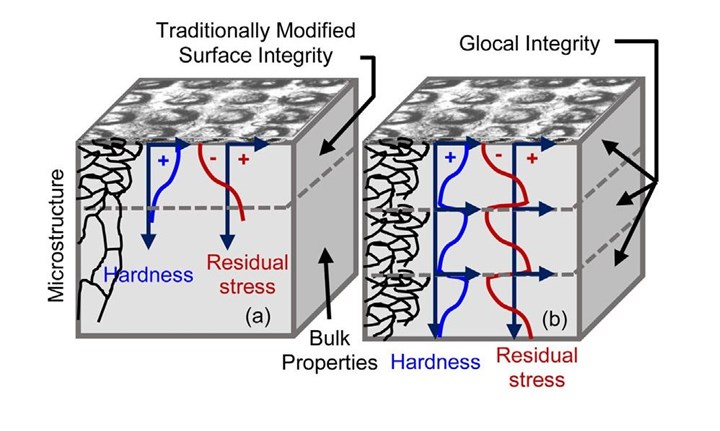

“‘Glocal’ is used in the business community to imply that local changes have global implications,” Sealy explains. “I’m applying that same concept to hybrid additive manufacturing. We’re doing local changes layer by layer that may have global implications.”

Applied to magnesium implants, this technique offers an exceptional benefit. Unlike more typical titanium and stainless steel medical devices which are more or less permanent, those made from magnesium can actually be absorbed by the body over time, allowing a patient’s own bone to grow back fully and potentially avoiding complications such as stress shielding. A “glocal” manufacturing strategy offers a way of controlling both the strength and longevity of the device, Sealy says. The research has the potential to impact the future of medical implants, as well as any application where manipulating the mechanical properties of a part this way might be beneficial.

Hybrid Manufacturing of Magnesium Implants

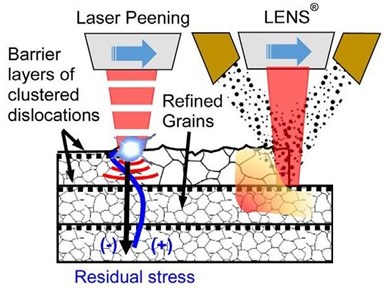

The specific technique used at UNL combines laser peening with directed energy deposition (DED) on an Optomec LENS 860 hybrid machine tool. The LENS platform uses the powder-based Laser Engineered Net Shaping (LENS) process to deposit material and build up parts, and is more commonly paired with milling capability in its hybrid configuration. At UNL, the system’s inert atmosphere makes it possible to 3D print with magnesium and immediately apply laser peening even after as little as one layer, without removing the part from the envelope.

In the “glocal” hybrid manufacturing approach used at UNL, material is deposited and melted in a first pass and then laser peened with a second pass, resulting in areas of tension and compression, respectively.

Medical implants made from magnesium aren’t new—they are already available in South Korea and parts of Europe. However, current implants are typically small, non-load-bearing items such as screws and pins, and made with conventional processes such as turning and extrusion. Sealy’s research is unusual for both the manufacturing process employed and its goal of manufacturing larger, load-bearing plates in magnesium.

“What we’re aiming for its to get to a point where if you break your femur, you have the ability to have a larger plate group construct that can support the weight of your body and also degrade in a controlled manner,” Sealy explains. “Something under compression is going to degrade very slowly, while something under tension is going to degrade really fast. With this method, you’re actually putting both compression and tension regions into your implant.” Areas treated with laser peening retain compressive residual stresses, essentially strengthening the material in those locations.

Traditionally surface treatments such as laser peening only affect the area near the surface of the part. Applying laser peening between 3D printed layers, however, can distribute mechanical properties and residual stresses throughout the entire part.

Applying Interlayer Laser Peening

In addition to changing the size and geometry of the implant per patient requirements, the hybrid glocal technique used in practice would enable adjusting for degradation based on factors such as age, gender and overall health. A growing 12-year old boy would need a faster-degrading femur implant, while a 70-year-old woman with osteoporosis would need the same device to last longer, for example. Interlayer laser peening has already been shown to be effective at altering mechanical properties in materials like stainless steel, aluminum and titanium. Current research at UNL is focused on learning to transfer the technique to magnesium, and determining how to apply “local” laser peening for desired, “global” effects like these.

These two samples illustrate the difference between a strictly 3D printed part (left) and one where laser peening was utilized after each layer.

“We don’t know if we should apply laser peening every layer, every three layers, or something more random like peen three layers, then skip two. Maybe it’s by region,” Sealy says. Past experiments in stainless steel and other materials were analyzed with Abaqus software from Dassault Systèmes to track redistribution of residual stress. These findings provide some insight into possible rules of thumb, but further research is needed.

“Our focus right now is finding a solution to the stress corrosion problem on a femur plate implant,” Sealy says. “The next step is figuring out all the solutions. Would an implant for a femur fracture have a different hybrid processing pattern than something like a clavicle plate? What is the right method to peen these implants so that you get the right performance?”

If it is possible to find the solution to the specific problem of a femur plate implant, Sealy says, the next steps will be to attempt to find it for all solutions—all patients, all implant locations, and eventually, applications beyond medical implants.

Benefits Beyond Additive Alone

Automotive is just one example of another industry that could benefit from a “glocal” hybrid manufacturing strategy. Autonomous cars for instance will have different needs than their counterparts currently on the road, many of which are privately owned and driven by a single driver.

“If you merge ride shares and autonomous vehicles, you could have a car that just continuously drives from point A to point B all day, every day,” Sealy says. “You’re completely changing the wear and tear on that engine. You might put something like 300,000 miles on that car in a single year. We didn’t design vehicles to drive 300,000 miles a year. You need manufacturing technologies that can keep up with that.”

“...more lightweight structures that have higher strength than you can achieve with just 3D printing by itself.”

Topology optimization software tools can help lightweight car parts to improve performance, but its benefits can only go so far. Topology optimization combined with interlayer secondary processes, however, could bring greater “glocal” benefits.

“If you could create your topology optimized structure, and then do a hybrid process on it layer by layer, then you may be able to get something 20% or 50% lighter,” Sealy says. “That’s what we’re aiming for, more lightweight structures that have higher strength than you can achieve with just 3D printing by itself.”