New Kimura U.S. Metal Casting Plant Relies Entirely on 3D Printing for Molds and Cores

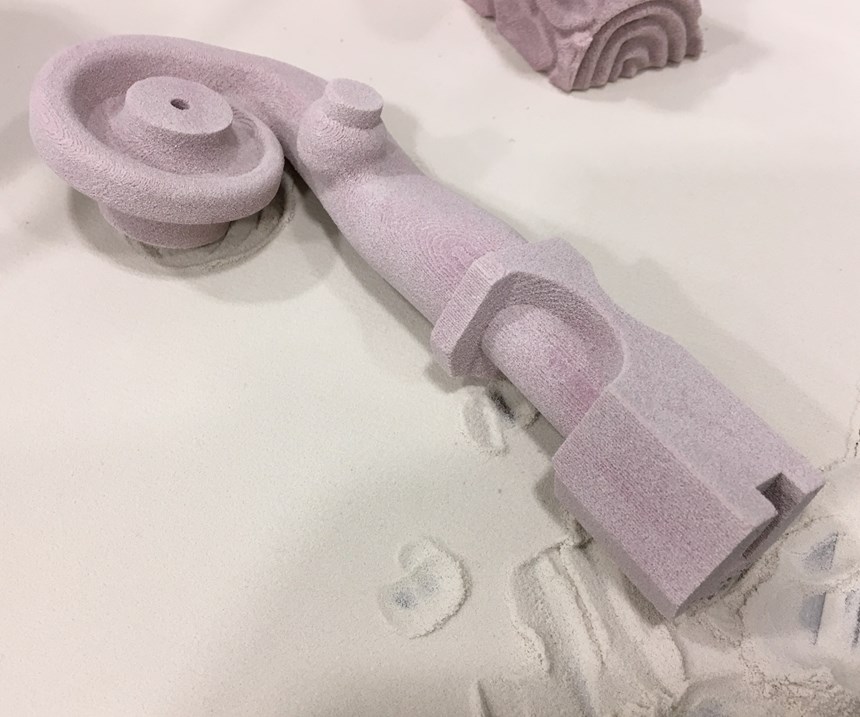

Printing foundry molds and cores without hard tooling will speed leadtimes and make small quantities of castings affordable, the company says. Its proprietary process advances the detail and finish obtainable from casting using sand 3D printing.

In Shelbyville, Indiana, I recently attended the opening of a new metal casting facility unlike any foundry I have seen. Where some foundries have begun to use 3D printing of sand for molds and cores as a complement to the foundry’s traditional approach of forming sand using patterns and core boxes, the new Kimura Foundry America plant will use 3D printing of sand for 100 percent of its metal casting work, departing from patternmaking completely. That commitment changes the pacing, workflow and order quantities possible in this plant. In addition, thanks to Kimura’s proprietary refinement of sand 3D printing (already being applied in its foundries in Japan), the company has improved the capabilities it is able to achieve with this technology. While leading me on a tour of the new facility, recently hired Kimura casting engineer Tyler Kroes motioned to the plant’s two sand printers from ExOne and made clear, “These systems are the heart of our process.”

The new plant, Kimura’s first U.S. facility, represents an $11.5 million investment, according to U.S. president Yoya Fakuda, Ph.D. Twenty-four people have been hired to staff the plant, mostly from the local area. Kroes in an exception to this; he was hired and relocated from the Detroit area, where he worked in a more traditional foundry setting. Indeed, his father worked in a foundry as well, so Kroes has been familiar with the nature of metal casting for much of his life.

The leadtime possible for this new plant is the shift that continues to impress him, he says. Removing hard tooling from the process removes a speed brake. The process to which he is more accustomed is, “Wait four weeks for a pattern, then test it, then if the job goes to production, you don’t see it again,” he says. By contrast, at this new plant, a leadtime of just one week will be typical for the complete process to obtain a raw casting, and the streamlined sequence of operations will have him routinely involved with each step in this process from casting design to 3D printing to the metal pour.

The lack of hard tooling also changes the economics of order quantities. With no need to create and amortize a pattern, ordering a single casting of a given geometry becomes relatively inexpensive. This is an aid to prototyping, he says. A customer could order, say, five design variations of a potential new part. The Kimura facility would 3D print all of the corresponding sand molds and cores, perhaps nesting all these pieces within a single build of the printer, and it would pour all five castings simultaneously. Five different parts with five different geometries thus could be produced for essentially the same cost as if all five parts had been alike.

The ExOne sand printing machines employ binder jetting, a 3D printing process that entails no support plate and no need for support structures. Because the loose sand itself is the only support necessary for parts as they are being printed, molds and cores made this way can be nested within all three dimensions of the printer’s build volume. As a result, any given build on either 3D printing machine at the Kimura plant will routinely produce various molds and cores for various customers all in the same cycle. The two ExOne sand printers here include a larger-volume unit that will generally be used for molds and a smaller, finer-resolution machine used for cores and work requiring the finest detail.

Kimura engineers in Japan have been applying machines such as this for some time and have made the technology their own. Dr. Fakuda himself has been a leader of the company’s technology development in this area. One ingredient of 3D printing as Kimura applies it is a soft, proprietary sand currently being shipped from Japan, though the company aims to find a U.S. source to produce it. This sand, in combination with the company’s approach to mold coating and other process considerations, permits fine details and smooth finishes surpassing what the company has been able to achieve in 3D printing using sand available off the shelf. This benefit directly affects the economics of casting, because the smooth finishes can translate to reduced need for postprocessing the cast part. In some cases, the smooth finishes can also augment the engineering possibilities of the end product. For example, with smoother cores, Kimura’s sand 3D printer can deliver smoother internal passages for its customers designing turbomachinery components. Smoother passages improve the airflow, meaning the advance of casting is also advancing the power and performance of the system in which the cast part is used.

Related Content

Foundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read More3D Printing Solutions to Support Investment, Sand Casting

3D Systems is highlighting a design strategy for better investment casting patterns, as well as a new machine suitable for the production of patterns for sand casting.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreAMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.

Read MoreRead Next

Foundry Says Robotic Sand Printing a “Game Changer” for Metal Casting

The Hazleton Casting Company augments its traditional foundry operations with additive manufacturing. A new sand 3D printing system is expanding options for the foundry’s customers in areas including legacy tooling, product development and design complexity.

Read MoreVideo: Sand 3D Printing at Hoosier Pattern

A pattern maker demonstrates is patternless approach to casting.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More