Methods Event Debuts Additive Manufacturing Offerings

The company’s investments around its partnership with 3D Systems will help smaller manufacturers succeed with additive.

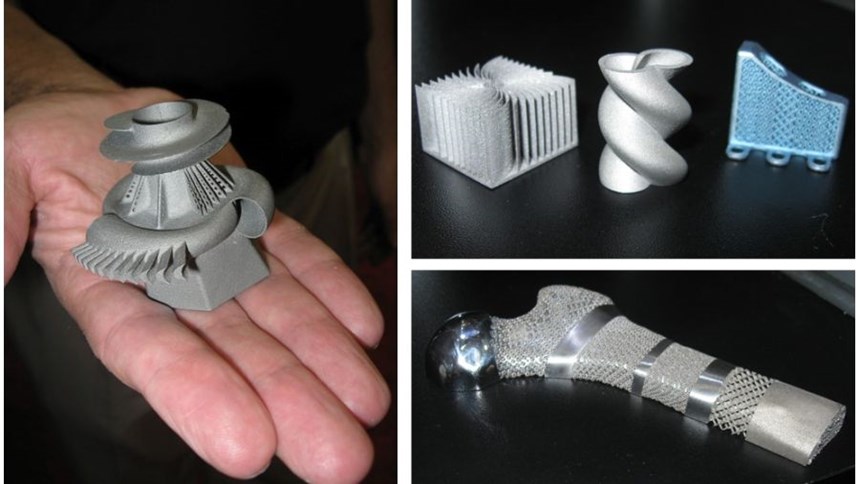

Methods Machine Tools’ “Techfest 2015” event was the public premiere of the company’s newly signed partnership with additive manufacturing technology supplier 3D Systems. Alongside its machine tool offerings from brands such as Nakamura-Tome, Kiwa, Yasda, Feeler, FANUC, Hanwa and Current EDM, Methods will now also supply 3D Systems equipment for additively producing polymer, ceramic or dense metal industrial parts.

Significantly, Methods says it will also help companies succeed with these additive technologies. In the machine tool sphere, the company aims to be a “solution” provider rather than solely an equipment provider, and it is known for turnkey installation of engineered systems combining machining technology with support equipment such as automation. Company President and CEO Bryon Deysher says the company will bring the same kind of engineering support to its sales of additive manufacturing technology.

“We are all in,” he said, describing his company’s commitment to additive manufacturing in remarks to an audience of attendees to the Techfest event. One of the challenges of additive manufacturing is that large companies can afford to invest in the learning curve necessary to succeed with additive, but small to midsize manufacturers struggle with this. He says Methods’ aim will be to fill this very gap, by staffing up with technical personnel focused on additive manufacturing who can guide customers along the way to successfully and efficiently applying this technology to industrial production.

Growing that staff will be part of Methods’ long-term investment in advancing additive technology, he says. He expects manufacturers will evaluate additive with a similarly long view. “I believe, if you are not thinking about this now, you’ll wish you were in two years,” he said at the event.

One of the company’s new hires is Benjamin Fisk. Until a couple of months ago, Fisk was a manufacturing technology manager overseeing AM efforts at Pratt & Whitney. Now, he has joined Methods as the general manager of what will eventually become a nationwide additive manufacturing team for the company, ready to support the AM efforts of companies much smaller and less well known than his former employer.

For these small and midsize manufacturers, he says, there are significant challenges today that inhibit additive manufacturing gaining ground. The burden of AM development and integration generally falls on users, he says. When it comes to development, a general lack of process knowledge leads to significant developmental costs. And when it comes integration, this effort has to be inclusive of a complete process from design through inspection.

“You can’t think about 3D printing as just a standalone process,” Fisk said.

Methods can help with this entire range of challenges, he says. The company can engineer a system for additive manufacturing that includes postprocessing equipment and other support capabilities. And it can assist customers to refine and prove out not just the additive portion of the process, but instead the entire part-making sequence including the additive step.

The Techfest event showed various equipment likely to be included in processes such as this. In a conversation with Fisk, I asked him to indicate machine tools at the event likely to be useful for processing 3D-printed metal parts. He pointed to wire EDM first, as this is frequently the best method for removing printed parts from their build platform. Next in the sequence might be a small five-axis machining center, he said—that is, a machine able to make the necessary finishing passes for the kind of geometrically intricate workpiece that additive manufacturing is able to produce.

Another capability seen at the event was robotic loading of both standalone and multiple machines. Integrating robots is a common part of Methods’ turnkey engineering. The company’s robotic installations to date have been for subtractive machine tools, but now this same kind of integration of automation might soon be applied to production processes involving additive manufacturing as well.

Read Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More