MC Machinery Systems to Offer Matsuura Lumex Additive Mfr. Machine

MC Machinery Systems, the Wood Dale, Illinois-based supplier of EDM machines, machining centers, press brakes, and laser and waterjet machines, has announced a partnership with Matsuura Machinery Corp. to introduce Matsuura’s Lumex Avance-25 additive manufacturing machine to the North American marketplace.

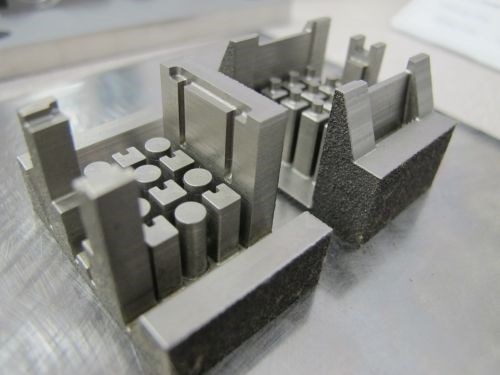

MC Machinery Systems, the Wood Dale, Illinois-based supplier of EDM machines, machining centers, press brakes, and laser and waterjet machines, has announced a partnership with Matsuura Machinery Corp. to introduce Matsuura’s Lumex Avance-25 additive manufacturing machine to the North American marketplace. The Lumex Avance-25 is a hybrid machine that not only builds parts through laser sintering, but also uses a milling spindle to perform precise CNC machining of the additively produced part within the same cycle.

MC Machinery Systems, wholly owned by Mitsubishi Corp., is well established in EDM machine sales to moldmakers. The company says this is why the partnership makes sense. Matsuura’s laser sintering hybrid machine was developed for making mold tooling, and it has been sold specifically in the die and mold industry in Japan and Asia.

“The moldmakers know us and know our people, and we’re excited to be able to offer them this innovative new technology,” says Nick Giannotte, MC Machinery VP for EDM, milling and waterjet.

Other applications present opportunities as well, the company says. MC Machinery and Matsuura see the machine also as a solution for medical implant production, and for enabling lighter-weight aircraft components. “All told, this machine will serve medical, automotive, aerospace, tool/die, and job shop industries,” a statement from the company says.

Related Content

-

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

-

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.