Material Improvement

In addition to the geometric freedom, additive manufacturing also provides the freedom to use metals that would be difficult to apply another way. Deka Research & Development is exploring both freedoms as it seeks to create a power source that could improve the lives of people around the world.

Have you heard of Mar-M 247? You might not have. I had not heard of this material before I visited Deka Research & Development. The nickel-based alloy with exceptional high-temperature strength is sometimes used in high-pressure turbines, and in the future, it just might figure into a solution for bringing power to impoverished parts of the world.

Deka is the Manchester, New Hampshire, company founded by Dean Kamen, the inventor known for the Segway human transporter and for the FIRST program that attracts young people to careers in science and engineering. Today, an ongoing focus of Deka’s attention is the Stirling engine. The company believes it can develop a modern version of the Stirling engine that takes advantage of today’s manufacturing technology to increase the power efficiency of an old and previously obscure engine design.

A Stirling engine runs on external combustion. Simply put: Burn any fuel beneath it, and the heat allows the engine to generate power. The concept was conceived and proven more than 200 years ago, but its shortcoming has always been the large bulk of this engine relative to its output. Stated another way, the shortcoming has been the small amount of power that can be generated by a reasonable-sized version of this engine running at reasonable temperatures.

But today it is likely that this shortcoming can be overcome. If so, the effect on the lives of people in the poorest parts of the world might be dramatic. If efficient and easily transportable Stirling engines can be sent into areas unreached by an electrical grid, then people in these areas could obtain usable power from whatever burnable material they might have at hand. Deka is also developing a water purifier that could run off this engine. However, key to realizing all of this promise will be to achieve that needed efficiency and transportability. As a result, this humanitarian challenge is inherently a manufacturing challenge.

Machine Shop Manager BJ Lanigan is one of the Deka team members working on that challenge. A resource he is now putting to use is a Concept Laser metal additive manufacturing machine Deka bought specifically for Stirling engine work. With this machine, Lanigan is making parts aimed at testing and proving out the Deka team’s various ideas for how to improve both the effectiveness and the manufacturability of critical components of the engine.

Additive manufacturing’s freedom to create complex geometries is well-known, and Deka is using that freedom to obtain intricate part geometries that seek to maximize thermal efficiency. Yet there is also a second, equally important area of freedom provided by additive. The various workpiece materials that are common in machine shops are not the only materials that are available to use. The materials known to shops are known specifically because they are machinable. But when additive manufacturing makes a part that is nearly complete—that is, a part that requires only simple machining steps to complete it—then machinability is much less of a concern. The palette of potential alloys grows. For Deka, this means that the options for improving an uncommon engine have now expanded to include uncommon metals.

Crazy Enough?

Lanigan could be said to have spent much of his childhood around Deka. Dean Kamen hired his father and his maternal grandfather before Lanigan was born. Growing up, he visited the shop routinely, and at age 17 he joined the company as a third-generation employee. Most of his work here so far has focused strictly on parts and processes, he says, but now his focus has changed. Just under two years ago, he was appointed machine shop manager, a role he knows he will need to grow into and to fill with humility, because at age 31 within a company of experienced professionals, he is very nearly the youngest person in the shop.

Deka has actually used 3D printing for many years. The company has been 3D printing plastic parts since the 1980s, and has an on-site 3D printing area with multiple machines. But when the new additive manufacturing machine brought the company the capability to produce critical metal production parts through an additive layering process, Lanigan says it became clear that this represented a change that went far beyond the possibilities of the shop’s previous 3D printing.

“I had the same thought others did,” he says. “I thought, ‘Wow, we will have to retrain our engineers.’”

Indeed, getting free of the unseen conceptual constraints harbored by experienced designers is a challenge the Deka team now continually confronts. Lanigan says, “When we design a part for additive, we look at the design and try to ask: Is this crazy enough?” Additive manufacturing permits elaborate geometries, and it realizes its full value when that freedom is embraced. “The danger is always that there is an even better design to be obtained through an even crazier geometry that we’re not able to see yet, because we are still locked into traditional ways of thinking about parts.”

Because of this kind of inquiry and design exploration, additive manufacturing actually works best in an environment like Deka’s in which designers and manufacturers work together. Design personnel sitting close to manufacturing personnel is what this process needs, Lanigan says. That makes it different from machining.

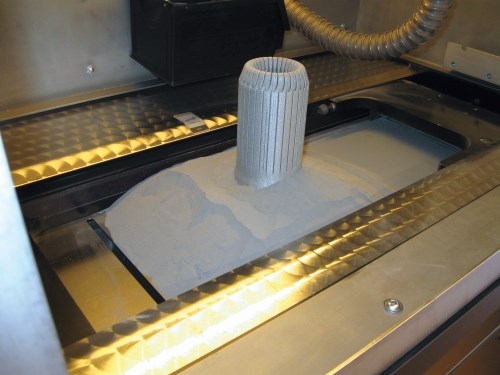

Another difference: trial and error. Precisely how a given part will form within an additive build is impossible to predict, he says. Residual stress during part formation might cause unacceptable distortions, and finding the way to avoid those distortions might involve changing the part orientation as well as adjusting process parameters such as layer thickness or laser scan speed. Because of this need to finesse the process, Lanigan says it is reasonable to expect to build any new additive part three or four times before getting to a successful process. This experimentation proceeds slowly, he says—the cycle to grow a Stirling engine heater head, for example, takes 22 hours. Thus, additive manufacturing is not a process for the impatient or the easily frustrated.

Heater Head

The heater head is the Stirling engine component that has benefited the most from additive manufacturing. This component is the heat exchanger at the heart of the engine’s operation. Flame fills the center of this head, heating helium carried through channels surrounding the fire.

On previous Stirling engines, this component would have been an assembly. Tubing to conduct the helium would be cut and bent into shape. However, the circular profile of off-the-shelf tubing is demonstrably not the best choice for thermal efficiency. Through additive manufacturing, company engineers have been able to grow heater head forms in which the passages carrying helium present profiles to the flame that achieve better heat transfer. Adding fins to the design, both inside and outside the channels, has also helped with this. Every such improvement in thermal efficiency is important, because greater efficiency ultimately results in a smaller engine to transport into a remote location, and less fuel for people in that location to burn to obtain a given amount of power.

In fact, a presumed disadvantage of additive manufacturing is actually a plus here. Within the tubes made additively, the rough surface characteristic of additive manufacturing helps to transition the helium from laminar to turbulent flow. This is a positive change, because the turbulent flow also enhances heat transfer.

Initially, heater heads were made from Inconel 625. That still might be the material that is ultimately used. But Mar-M 247, which is even better than Inconel at retaining its strength at high temperatures, might permit a more compact or efficient design. If this alloy is to be used, then additive is essential, because building the head through traditional assembly would not be possible. Machining the metal is so difficult, says Lanigan, that off-the-shelf tubing made of this material cannot be obtained.

Actually growing the part in this material will not be any more difficult than growing it in Inconel, he says. The challenge instead will relate to postprocessing. As yet, it is unclear whether or how a Mar-M 247 heater head can be treated to make it helium-tight. Helium is a tiny atom—effectively even tinier than hydrogen, because hydrogen exists as a molecule. With Inconel, Deka has found that hot isostatic pressing could be applied to enable the additively grown heater head to contain helium. Can a similar process do the same for the less familiar alloy? Deka is seeking the answer to that question.

Off the Grid

Other questions will follow, says Lanigan. Even after the problems of design and manufacturing are worked out, he says, commercialization will be a challenge. After all, the intended beneficiaries of this engine—the most poor—obviously lack financial means. To fund the full-scale manufacturing of the engine, Deka therefore hopes to find additional markets for it in wealthier economies. One possibility is people wishing to live off the grid in the United States.

The need to face this very question arguably highlights the difference between the inventor and the engineer, because for inventors, the challenges continue even after the engineering is done. But success in one area ought to contribute to success in the other. For Deka, the hope is that the engine design made possible through additive manufacturing will also make the engine attractive to those consumers who have the means to cover its costs.

Related Content

Spherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More