Largest ExOne Metal Binder Jetting System Yet Provides 160-Liter Build Volume

The design of this machine anticipates scale production, with compaction technology for repeatable part density and Industry 4.0 connectivity for lightly staffed AM factories.

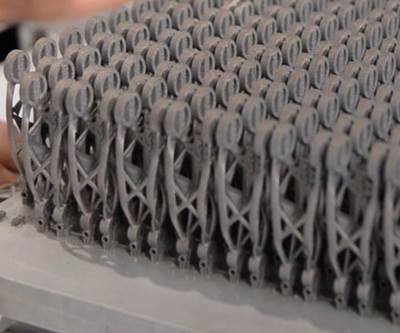

ExOne has announced the release of its new X1 160Pro binder jetting machine. With a build volume of 800 × 500 × 400 mm, or 160 liters, the machine the company’s largest metal additive manufacturing (AM) machine to date. The machine will be shown for the first time at Formnext 2019.

According to ExOne CEO John Hartner, the machine answers a need from customers to bring the design freedom of additive manufacturing to larger parts. However, just as importantly, the machine is a response to the advance of AM into larger production volumes. The larger build volume increases the batch quantity of smaller parts than can be produced in a single build.

Binder jetting is being accepted as “the serial production solution,” Hartner says. Among other things, the increase in suppliers of binder jetting machines illustrates this. Serial production is the application ExOne has always seen for the technology, he says, though developing systems that can deliver repeatably dense parts was an enabler to advancing this promise. Leveraging ExOne’s “Triple Advanced Compaction Technology” for controlling fine powders and realizing consistent high density, the new machine is a repeatable metal binder jetting system suited to scale production. “Our technology roadmap has been leading us to this machine for two decades,” Hartner says.

Binder jetting is 3D printing in which a binding fluid bonds powder, layer by layer. The resulting part is then sintered to final hardness. No melting is involved. In production, one of binder jetting’s advantages over other metal AM systems is speed. The binder fluid head offers jets moving in parallel, as contrasted with a laser having to move in a back-and-forth “raster” pattern over the same area. ExOne’s new X1 160Pro achieves print speeds up to 10,000 cubic centimeters per hour, depending on material. The six qualified metals for the system include three varieties of stainless steel, two stainless options infiltrated with bronze, and bronze-infiltrated tungsten. Beta materials include Inconels, tool steels and others. An open material system allows ExOne to work with customers on the use of other metals, as well as ceramics, which can also be 3D printed with binder jetting.

Hartner notes that the solution developed for production anticipates a likely use that largely hasn’t been realized yet: unattended or lightly attended facilities full of AM machines running round the clock. The new machines provide Industry 4.0 connectivity enabled by Siemens MindSphere. “Essentially, every sensor on the machine can be made visible to the cloud,” Hartner says. Potential users largely don’t recognize the need for this yet, but they will. “We talk about the value AI and machine learning will bring to manufacturing, particularly additive manufacturing, but first you need data! We’ve got the machine piped to deliver that data.”

He notes the machine also joins a product line suitable to users who don’t yet know how far into production they might go. “With our product family now, there’s a path. A user can start with a 1-liter machine, go to 25 liters, and now go to 160 liters when production demands scale that high.”

Related Content

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreRead Next

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreAdditive Manufacturing Is Succeeding in Production! Here Are Examples

We are no longer predicting that additive manufacturing will be used in production — because it already is. Find real stories of 3D printing for full production at AM's leading edge in this collection.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More