Desktop Metal’s Production System P-1 Features Optional Reactive Safety Kit

The kit features ATEX-rated components, as well as critical hardware and software updates that enable safe printing of ultrafine powders.

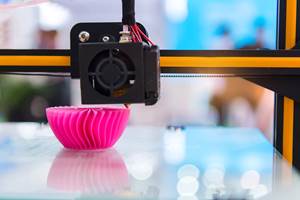

The P-1 is capable of processing 17 metals, but a Reactive Safety Kit is required for 3D printing titanium and aluminum. Source: Business Wire

Desktop Metal is now offering its Production System P-1 with an optional Reactive Safety Kit to unlock safe, high-speed binder jet 3D printing of both titanium and aluminum.

Tested by Detroit-based TriTech Titanium Parts, the kit features ATEX-rated components, as well as critical hardware and software updates to ensure the highest level of safety. ATEX certification is given to equipment that has undergone rigorous testing outlined by European Union directives and is considered safe to use in specific environments with explosive atmospheres.

First launched in 2020, the Production System P-1 metal binder jet 3D printer now offered with a Reactive Safety Kit can unlock high-speed production of ultrafine titanium and aluminum powders with critical safety features. The P-1 uses Desktop Metal’s patent-pending, high-speed Single Pass Jetting (SPJ) technology in an inert environment and can complete each part layer in less than 3 seconds, depending on material, with full builds printable in less than one hour.

The P-1 is well suited for R&D scaling to full production on large binder jet systems and batch or serial production of small, complex parts. A number of DM customers are already binder jetting titanium and aluminum.

Detroit-based TriTech Titanium Parts, an experienced manufacturer of titanium parts for the commercial and industrial markets, has been testing the P-1 with a Reactive Safety Kit for two years and is now printing both titanium and aluminum parts.

DM currently has contracts with six major manufacturers — four in the automotive industry, one in commercial lighting and another medical implant firm — to scale titanium and aluminum projects, with an eye on serial production of complex components. Large aluminum parts are now being 3D printed for qualified customers at Desktop Metal’s Burlington headquarters using an upgraded X25Pro with a 25-L build volume

“Titanium and aluminum are two of the most frequently requested materials at Desktop Metal, and we’re proud to say that we can now offer a commercial 3D printer with the necessary safety features to binder jet 3D print these materials,” says Ric Fulop, Desktop Metal founder and CEO. “Based on our ongoing projects with major manufacturers, we know our technology is well on its way to unlocking new designs that deliver higher performance, weight reductions, and other benefits — all with our high-speed 3D printing technology that makes additive manufacturing more affordable for production volumes. We are diligently following our road map to deliver high-volume production of these materials on our largest printers in the future.”

Binder Jetting Offers Range of Benefits

Binder Jetting is one of the fastest methods of metal 3D printing for high-volume output. It uses a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand or ceramic to create a solid part, one thin layer at a time. When printing metals, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object.

Binder jet 3D printing, compared to both traditional manufacturing and other forms of 3D printing, enables manufacturers to more affordably produce complex parts with unique benefits, such as size and weight reductions, part consolidation and performance improvements.

“Our team at TriTech has found binder jetting to be a good complement to our metal injection molding business,” says Robert Swenson, TriTech owner and former owner of AmeriTi. “With binder jet 3D printing, titanium production of even the most complex geometries can be greatly simplified and achieved at a lower cost. We’re excited to offer this cutting-edge manufacturing technology to our customers.”

Because of the broad material flexibility of binder jet 3D printing, Desktop Metal employs a tiered qualification system for production of powdered materials:

- Qualified Materials come with complete printing and sintering profiles with fully characterized material and mechanical properties.

- Customer-Qualified Materials have printing and sintering profiles developed by or in partnership with customers and/or partners with material and mechanical properties suitable for specific applications.

- R&D Qualified Materials have demonstrated binder and process compatibility with Desktop Metal printers, with final printing and sintering profiles under development by DM or our customers.

In all, more than 30 metals and ceramics are qualified on Desktop Metal printers. The Production System P-1 is qualified to 3D print 17 metals, including stainless steels, low-alloy steels, copper alloys, tool steels, nickel-based alloys, precious metals and more.

Titanium (Ti64) is now classified as Customer-Qualified on both the P-1 and X-Series models when upgraded with an inert atmosphere and other safety features. Aluminum is now classified as Customer-Qualified on the X-Series and R&D Qualified on the P-1 when upgraded with an inert atmosphere and other safety features.

Related Content

Chromatic 3D Materials' RX-AM Free of Volatile Isocyanates

RX-AM platform includes software and RX-Flow printers for use in standard and custom configurations.

Read MoreAddUp Receives ASTM Additive Manufacturing Safety Certification

AddUp Inc. announces that it has received the ASTM Additive Manufacturing Safety (AMS) Certification, becoming the first OEM in the AM industry to achieve this significant milestone.

Read MoreDurable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read MoreSLM Solutions, Assembrix Work to Ensure Secure Remote Printing

Following the integration of Assembrix VMS software into SLM Solutions’ machines, both companies are now working to ensure the enhanced safety and full protection of customers' intellectual property, which is made possible through the utilization of blockchain and encryption technologies.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More