With Machine Learning, We Will Skip Ahead 100 Years

Machine learning or AI will prove vital to the advance of AM. Computational power will enable additive to advance much faster than if it had been invented in an earlier time.

Every part-making process is subject to variables that affect its outcome, but with additive manufacturing (AM), there is a difference of degree. In machining, for example, we know the impact of choices of tooling, cutting fluid, feed rate and so on, and in molding we know the effect of characteristics of the material and mold design. But when it comes to an additive process such as selective laser melting in metal, there are more variables and more combinations of variables affecting the form and properties of the part than we have yet recognized, let alone mastered.

However, additive will benefit from one other important difference: a difference of timing.

Other manufacturing processes came of age well in the past. Additive is maturing during a time of advanced computing power. As a result, it appears likely that machine learning—the theme of this month’s issue of Additive Manufacturing—will prove to be a major factor in the way that AM advances.

Specifically, machine learning will enable the speed of AM’s advance. The term does not imply a type of calculation humans can’t do, but instead a volume of calculations. A billion different relationships among many inputs and outputs can be explored rapidly through computation, whereas just a fraction of the same exploration might take human beings working on their own something like a century to carry out.

We know this, because in the past, we have had no choice but to spend that century. For example, some past year’s new cutter design for machining might have drawn upon research begun ten or more years prior. Our knowledge proceeded slowly in this way, even generationally, with researchers exploring process variables exclusively through experimentation and their own inference of what they saw. The early successes in AM came the same way.

The new way knowledge and successes will come can be glimpsed in this month’s coverage. Three feature articles this month (related to process control, materials and AI-driven decision making) describe how machine learning is being used as a tool to more rapidly advance our mastery of AM.

And a tool is just what machine learning is, says Bryce Meredig, co-founder of Citrine Informatics, the firm applying this tool as part of the research discussed in this article. Machine learning is a different kind of tool than anything manufacturers are accustomed to, but it is one they will not only come to understand, but also make better through their efforts. He uses the term “artificial intelligence” (AI), and to him, “artificial” captures both the tool’s power and its limitations.

“AI is really good at taking a billion possibilities and short-listing them to ten,” he says. “But humans have important pieces of understanding that are too subtle to incorporate into computation.” Thus, only a human can look at a set of possibilities produced by machine learning and see something like, Options one and two are not feasible, but option three is a promising way to go.

Success will lead to success, he says. Progress will accelerate because mathematical relationships will be found that point to physically meaningful relationships. Rules will be found. And when a rule is discovered—that is, do X in selective laser melting of Inconel 718 and it reliably leads to Y—then that knowledge can be incorporated into the model, allowing subsequent machine learning to accept the rule as known and direct its power elsewhere.

Humans will find the rules, he notes. That much will remain as true as it ever was. As computation identifies promising connections between inputs and outputs, human experts will judge which findings are noise and which make sense. It is simply the speed of discovery that will change, but this change will be profound, and we will even see it accelerate. That is, as people continue to perform the crucial last step of recognizing the value in AI’s findings, he says, that very contribution will also allow the pace of those findings to increase.

Related Content

5 Observations From Dr. Tim Simpson About the State of Additive Manufacturing So Far

The outgoing co-director of Penn State’s CIMP-3D takes stock of how far AM has come, aided in no small part through the work of the organization he helped to lead.

Read MoreArtificial Intelligence and Additive Manufacturing Are Connected: AM Radio #36

Stephanie Hendrixson and Peter Zelinski discuss how AI and AM go together. There are already plenty of uses of AI in 3D printing for design, process planning and process monitoring, and the link will grow stronger as the “frictionlessness” of AI blends with that of AM.

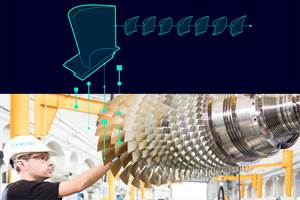

Read MoreSiemens’ Engineering HEEDS AI Simulation Predictor Optimizes Additive Manufacturing

The HEEDS AI Simulation Predictor empowers organizations to take full advantage of the digital twin to optimize products through advanced state-of-the-art artificial intelligence with built-in accuracy awareness.

Read MoreLessons in Personalized Production From the 3D Systems Surgical Guide Process

Tailor-made manufacturing is one of AM’s richest possibilities, but the success factors inevitably draw on more than AM.

Read MoreRead Next

How Machine Learning Is Moving AM Beyond Trial and Error

A Colorado alliance has found the link between AM and AI. Using machine learning to map the formula for successful metal 3D printing, researchers aim to know the right parameters for any new part with few or no test builds.

Read MoreWhat GE’s Machine Learning Ecosystem Will Mean for Additive Manufacturing

At GE’s Global Research Center in upstate New York, engineers join forces to build a digital library of additive research.

Read MoreComputer Vision System Automates Characterization of Metal Powder

A computer vision system that has learned to classify metal powders could speed material qualification and advance machine learning in additive manufacturing.

Read More