Share

Read Next

The F-35 Lightning II Joint Strike Fighter program is one of the most expensive and technologically ambitious engineering and manufacturing programs the world has ever known. When Lockheed Martin, the contractor for the F-35, initiated a pilot scale implementation of additive manufacturing in an effort to cut costs for the F-35 nearly a decade ago, the pilot program utilized large-scale electron beam additive manufacturing (AM) with the alloy Ti-6Al-4V. But while this alloy is the same material used in forged structures on the aircraft, the fabrication process—additive—was entirely different, and thus required a requalification of the material for the AM process. And that’s where things got sticky.

It’s not unusual for performance demands in the defense sector to cause costs to skyrocket. This is especially true within aerospace, where critical structures often require a statistically validated qualification process that can entail thousands of tests in order to define and certify the mechanical properties and behavior of a new material. In 2011, Craig Brice, then a materials research engineer with NASA Langley Research Center, foresaw that aerospace qualification processes and additive manufacturing technologies were on a collision course. In a paper Brice produced that year for the 1st World Congress on Integrated Computational Materials Engineering, titled, “Unintended Consequences: How Qualification Constrains Innovation,” he made his point clear:

“The data generated under the qualification program effectively ‘fixes’ the materials and procedures in place and requires the process to become static. While this is desirable and necessary for a standardized and repeatable process, it also limits the ability to seek improvements in the process (and in the materials generated by the process). The additive manufacturing approach allows for more degrees of freedom in the fabrication process. Multiple process paths can yield the acceptable end product, both microstructurally and mechanically. Furthermore, the conditions and/or material chosen in the qualification study may turn out to not be the ideal path as the process evolves and matures. Unfortunately, any excursion from the standard deposition process, as established in the specification procedures, will not be allowed under the current methodology. The challenge for the additive manufacturing community is that the process segment of the process-microstructure-property relationship is not necessarily uniform or static. This implies the need for an outcome-based approach for material qualification.”

In other words, he argued, the same qualification process that keeps planes from falling from the sky will, in a future that includes more and more aerospace parts produced additively, make it much more difficult for new aircraft to leave the ground. Therefore, he said, as long as the microstructures of the material are identical, qualification processes should focus on the outcome, not the path it took to get there.

If the qualification process is a major impediment to the deployment of additively produced parts, the challenge is to streamline the way in which we prove sufficient microstructure similarity to certifying agencies. This would require computational methods not typical of other manufacturing processes. But, perhaps more significantly, it would also require partnerships, notably between public and private sectors, to an extent other manufacturing challenges simply haven’t required.

As it turns out, Brice wasn’t the only one who recognized this need.

Processes < Outcomes

In Colorado, one of the largest per-capita aerospace employers in the U.S., Faustson Tool is a highly regarded machine shop within the industry. Owner Alicia Svaldi and vice president Heidi Hostetter have helped Faustson Tool earn its reputation for precision machining capabilities and high-profile work, such as a key component in NASA’s Kepler space telescope, as well as parts for the U.S. F-35 Lightning II Joint Strike Fighter jet in conjunction with Ball Aerospace. The company added metal additive manufacturing capabilities to its shop floor back in 2014.

Hostetter in particular is well known in Colorado for her political acumen for advancing AM—a sort of Rocky Mountain evangelist for additive who crisscrosses the state, networking on behalf of Faustson as well as H2 Manufacturing Solutions, her consulting service for advanced manufacturing. So in 2014 when Colorado Governor John Hickenlooper pushed forward infrastructure legislation to start an advanced industry accelerator branch fund, Hostetter seized the opportunity. The grant proposal stipulated that the accelerator would have to benefit the state’s seven top industry sectors, and involve private industry and a nonprofit as well as an academic institution. Hostetter pitched her idea to compete for the grant to Dr. Aaron Stebner, an associate professor of mechanical engineering and materials science at Colorado School of Mines, widely recognized as one of the top materials science schools in the country.

“...these weren’t four- or five-year research projects. These were like, ‘I need some data and an answer tomorrow’ kind of projects, which is not what a university usually does by default.”

“Around 2013, we had a lot of front range companies coming to School of Mines for help with metals additive,” Stebner says. “Some of them had bought AM machines and didn’t understand why they weren’t getting the quality that the salesman promised. And it took us a while to figure out how to help them, because these weren’t four- or five-year research projects. These were like, ‘I need some data and an answer tomorrow’ kind of projects, which is not what a university usually does by default.”

As it turned out, Craig Brice was leaving NASA to rejoin Lockheed Martin, this time in Colorado, when Stebner introduced him to Hostetter and her idea to create an additive accelerator program at Colorado School of Mines. “They took the idea and refined it into a data-driven center that could track numerous variables having to do with microstructures and material properties,” Hostetter says. The group was able to secure commitments from Ball Aerospace, Lockheed Martin and Faustson, as well as the Colorado Manufacturers Extension Partnership program, Manufacturer’s Edge, on the proposal.

In December 2015, the group won the largest grant the state had ever awarded—$2.5 million—and the Alliance for the Development of Additive Processing Technologies (ADAPT) Center was born.

“I was scared to death when we won the grant money,” Stebner says. “We didn’t really have any additive manufacturing faculty at that time, and I was wondering whether everybody I hired would be out of a job in 12 months.” But in the three years since the grant award, the opposite has been true. The ADAPT Center has raised more than $20 million in external funding, grown from three member companies to 20, and stood up a full professional degree program and curriculum in advanced manufacturing as well as a master’s practicum program in additive manufacturing run by several new faculty members.

Today, the center’s mission still ties back to the core argument Craig Brice put forth while working for NASA: to decode the fundamental physics of energy input, mass flow and time for additive manufacturing processes in a way that allows AM outcomes to drive the qualification programs. And the only way to do that is through the generation of data.

Find, Distill, Influence

The ADAPT Center is, in essence, a centralized repository of certified, nonproprietary test data. While the center has added a number of additive manufacturing machines (which was not the case as recently as this past February when we wrote about the link between artificial intelligence and AM being studied at the center), the center was fundamentally established to address the data challenges in additive manufacturing. Crucially, that data has to be collected in a manner that encourages would-be competitors to feel comfortable that they are not exposing proprietary information or risking their intellectual property (IP).

Of course, not all companies define their IP alike. For example, the additive machine settings utilized by a smaller company or service bureau to create parts is often protected information. Conversely, a large company like Lockheed Martin doesn’t operate by running additive machines to create parts, but (typically) purchases parts from smaller companies and service bureaus. So, from a Lockheed perspective, if it can get the smaller company’s pre-competitive data—data from examining test samples, for example—out and into a collaborative environment, that data can drive its service bureaus to improve their product.

“So, setting A on the machine might be some kind of proprietary setting that the machine manufacturers developed… But we can distill that down into the fundamental quantities of energy per unit area, which doesn’t give away anybody’s secret in terms of the position of that knob on their machine.”

The sheer number of settings in metal additive manufacturing machines—the “thousand knobs to turn” conundrum of the process variables—is a problem exacerbated by the fact that two different companies using different machines (or even the same machine) may use completely different settings to achieve similar microstructures for otherwise identical parts. The ADAPT Center is trying to draw correlations between the processing and the properties. “So, setting A on the machine might be some kind of proprietary setting that the machine manufacturers developed,” Brice says. “But we can distill that down into the fundamental quantities of energy per unit area, which doesn’t give away anybody’s secret in terms of the position of that knob on their machine.”

And those scientific and fundamental quantities can be transferred between equipment providers. In other words, the ADAPT Center aims to decode the fundamental physics of energy input, mass flow and time, and allow those fundamentals to dictate how an additive process is occurring.

For instance, last year Lockheed Martin was in the process of qualifying material to make propellant tanks for satellites. While the work was occurring in a very narrow space for a very specific application, the data that the ADAPT Center could collect while Lockheed performed the work would be potentially and broadly valuable to the entire AM community. Since Lockheed is an ADAPT Center member, the center has been able to collect excess material and scrap that’s either post-tested or hasn’t been tested, and sample that data as well as the parts. Because this excess material is being used in a qualified aerospace process, the center can use that data to formulate connections between outcomes and qualification programs. Once this data is entered into the center’s master database, Brice argues, it will reduce the need to recreate massive datasets through retesting after changes to an additive process. This sort of equivalency testing also reduces the cost barrier for a new supplier and opens up the supply chain.

“If we can help influence how certifying agencies such as DoD, FAA and NASA approach process and material qualification and part certification for additive parts, I think we’ll have been successful,” Brice says. “You have to come up with a construct that gives them the confidence that what you’ve done meets scientific and statistical rigor so that you know airplanes aren’t going to fall out of the sky. There are a dozen different companies supplying equipment in the powder-bed metal additive space. You don’t want to have to treat each of those suppliers as unique. There has to be some commonality, which is what we’re driving to here at the ADAPT Center: find that commonality, distill it down to the fundamentals, and influence how materials from additive processes are qualified for use in critical applications.”

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

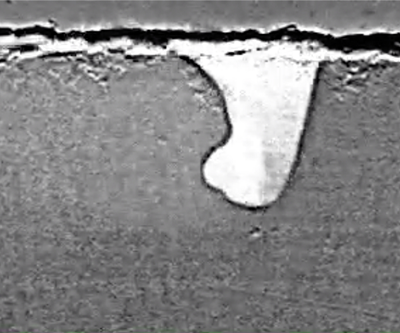

Carnegie Mellon University and Argonne National Laboratory Seek to Understand Gas-Driven Micro Defects in Metal AM Parts

Better understanding of "keyhole" formations resulting from boiling metal will lead to better control over laser powder-bed fusion.

Read MoreCan Topography Scans Redraw the Metal Additive Inspection Map?

A new topographical mapping technology aims to detect, record and display flawed metal melt regions as they’re created.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More