Gefertec, Linde Partner on Additive 3DMP Research

Gefertec and Linde have partnered with two other companies to research Gefertec’s 3DMP 3D printing process and ultimately determine what gas and oxygen percentage needs to be used to optimize high-production of larger titanium alloy parts.

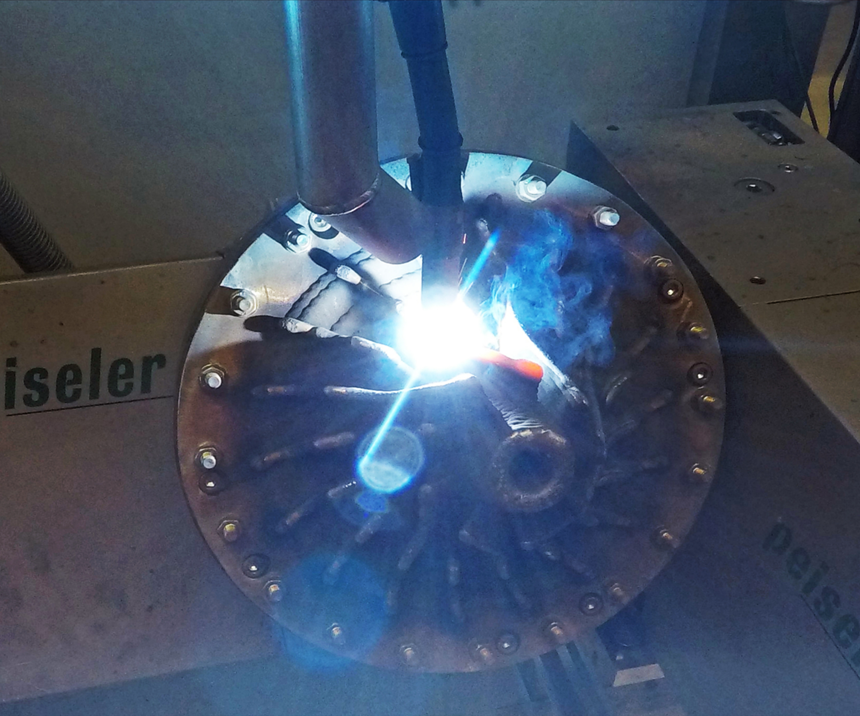

Gefertec and Linde AG have started a joint research project to investigate the influence of the process gas and the oxygen percentage on Gefertec’s 3DMP 3D printing process. Along with the two companies, MT Aerospace AG is joining the partnership and will perform the mechanical tests of the produced parts. The actual 3D printing will take place at the additive manufacturing laboratory of Fraunhofer IGCV—the fourth cooperation partner, and where Gefertec will install the 3D printing system. According to the collaboration, the final goal of the project is the high-speed production of larger parts made of the titanium alloy Ti6Al4V, which meets the quality requirements of the aerospace industry.

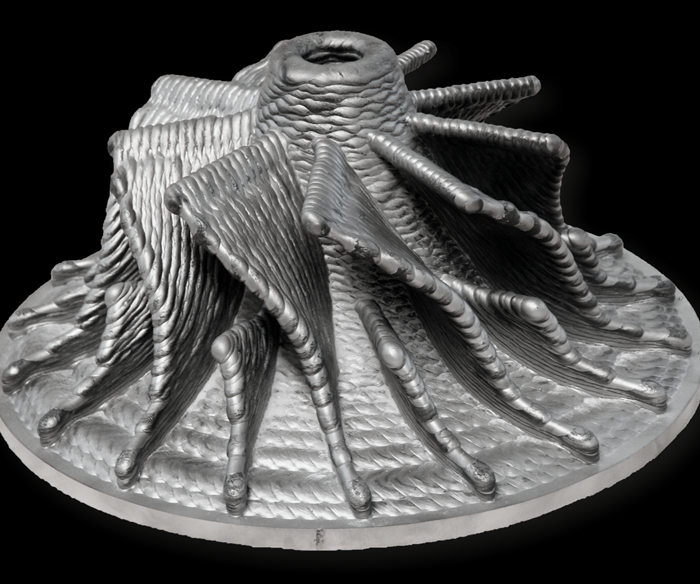

The Gefertec 3DMP printing technology uses electric arc welding and wire material to create a near-net-shape part formed by welding layer by layer. After 3D printing the part can be further machined by conventional milling. For larger parts, this technology is said to be faster and more cost-effective compared to other methods based on powder as original material. The result of the arc welding process depends heavily on various parameters—especially from the process gas.

Related Content

-

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.