Benchmarking: How Do Metal 3D Printers Really Compare?

When serial production is the goal, quality is paramount. Contract manufacturer Cumberland Additive shares a benchmarking experiment comparing two of its powder bed fusion metal 3D printers in this presentation from AM In-Depth.

As additive manufacturing (AM) has taken hold as a production method, companies that wish to take advantage of this technology are also inherently concerned with quality. AM is still a young process and 3D printers can vary widely in terms of capabilities and consistency.

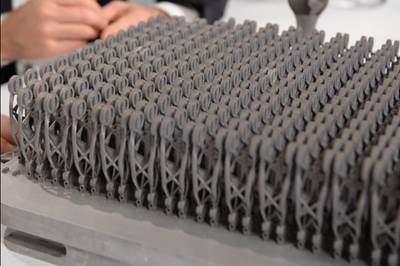

Ensuring repeatability across metal 3D printers was a topic of discussion during AM In-Depth, an educational series housed within IMTS Spark. Brenna McCornac, additive manufacturing engineer with Cumberland Additive, shared a benchmarking experiment in which the company compared two of its powder bed fusion (PBF) metal 3D printers from different builders.

“I intended for all of these specimens to fail,” McCornac said, pointing out that the benchmarking tests were designed to push the 3D printers to their limits. Builds that succeeded offered insights into the geometric capabilities and strengths of each platform. Watch the recording.

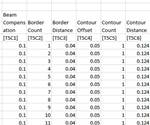

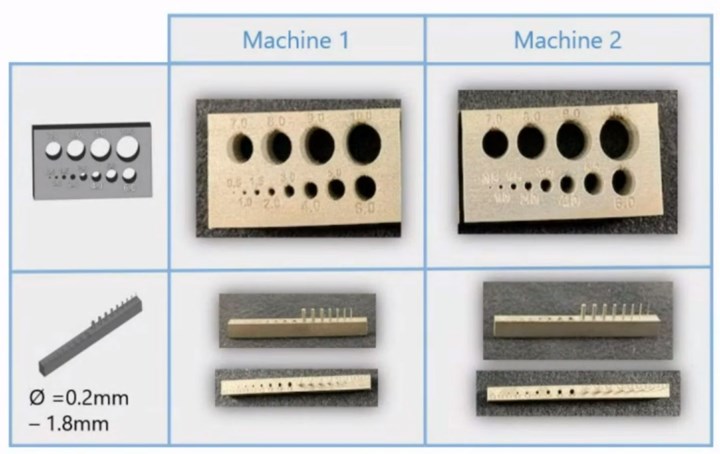

The two 3D printers were run through a series of tests using Ni718 powder from the same lot as a way of better understanding how they function during normal use and the particular strengths or weaknesses of each system when using this material.

The 3D printers were evaluated on the following factors:

- Plate heating. Interestingly, the build plate temperature reported by each system was less than that found by thermocouples placed on top of their print surfaces, due to plate heaters being located below the plate; understanding this discrepancy could help users achieve better consistency through longer preheating steps or by checking temperatures independent of the system sensors.

- Tensile properties. Test builds with artifacts scattered across the plate resulted in parts with better elongation than indicated by either 3D printer manufacturer, but slightly less yield and ultimate strength than expected. Additive manufacturing users have an obligation to evaluate the tensile properties of builds themselves, she says, rather than rely on documentation from the printer supplier.

- Geometric capability. In several cases the metal 3D printers were found to be more capable than manufacturers’ guidelines suggested; one system successfully printed an overhang of 35 degrees, for instance, despite a minimum overhang recommendation of 45 degrees. Holes, pins and thin walls were also evaluated, with the results indicating that some 3D printers may be more capable and reliable at creating certain features.

- Gas flow. One of the 3D printers suffered from a dead zone with poor gas flow in one corner, resulting in a degradation of mechanical properties there. In this case, Cumberland Additive worked with the printer manufacturer to upgrade the system and correct the issue. In cases where that is not possible, having an accurate benchmark of build locations within a machine can help ensure quality by guiding part placement.

For more detail on the benchmarking tests used as well as some advice for additive manufacturers pursuing benchmarking in service of serial production, see the recorded session.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreWhat Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

Read MoreRead Next

6 Things I Learned about Metal 3D Printing at the AMIST

I sat in on one and a half days of a five-day class offered at the Additive Manufacturing Institute of Science and Technology (AMIST) in Louisville. Here’s just some of what I learned.

Read MoreThe Case for Additive Manufacturing in Production

3D printing may have started out as a rapid prototyping technique, but the machines and materials have matured to the point that production is not only viable, but desirable, in many cases.

Read MoreYour Metal AM Process Development Tool? A Spreadsheet (Includes Video)

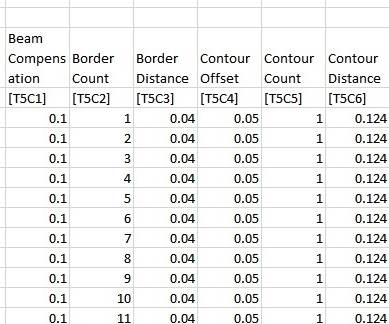

Spreadsheet integration with Renishaw software allows for fast programming of metal additive manufacturing test builds. Watch video for demonstration of defining many laser parameter combinations for use in a single test.

Read More

.jpg;width=70;height=70;mode=crop)