Additive Manufacturing’s Assist to ID Grinding

Additive manufacturing helped Norton/Saint-Gobain achieve better cooling in a grinding application.

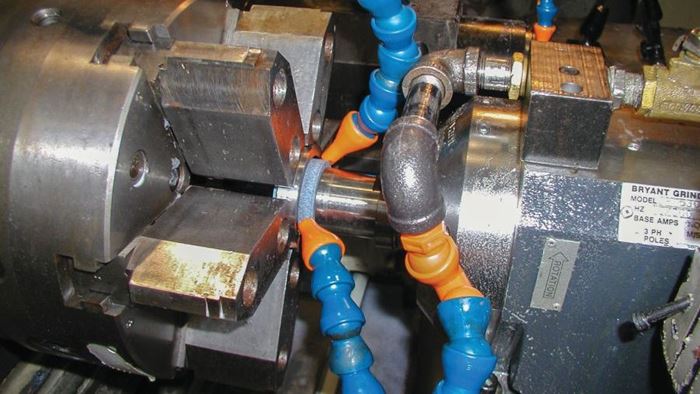

ID grinding involves machining a bore using a grinding wheel nearly as large as the bore itself, as shown in the large photo above. Coolant has to reach and cover the wheel through the narrow space between the wheel and the part. It often fails to do this, particularly on deeper bores than the one seen here, so the detrimental effect on surface quality and cycle time resulting from inadequate cooling is an accepted fact of life in ID grinding.

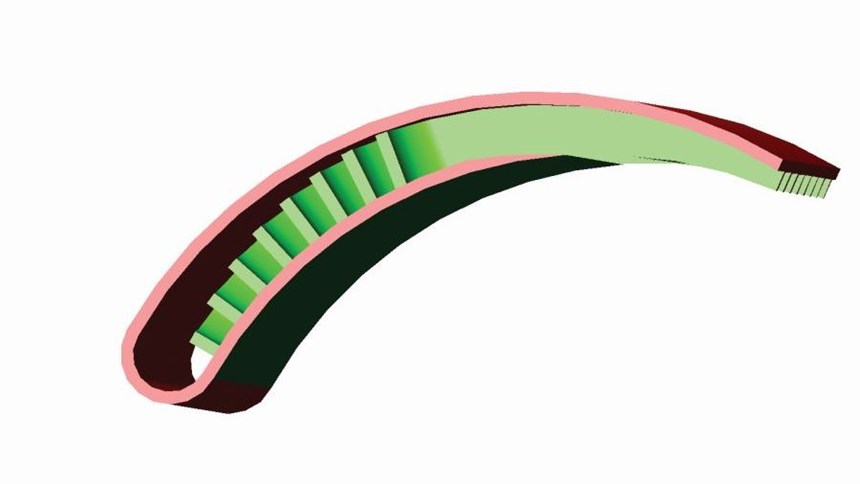

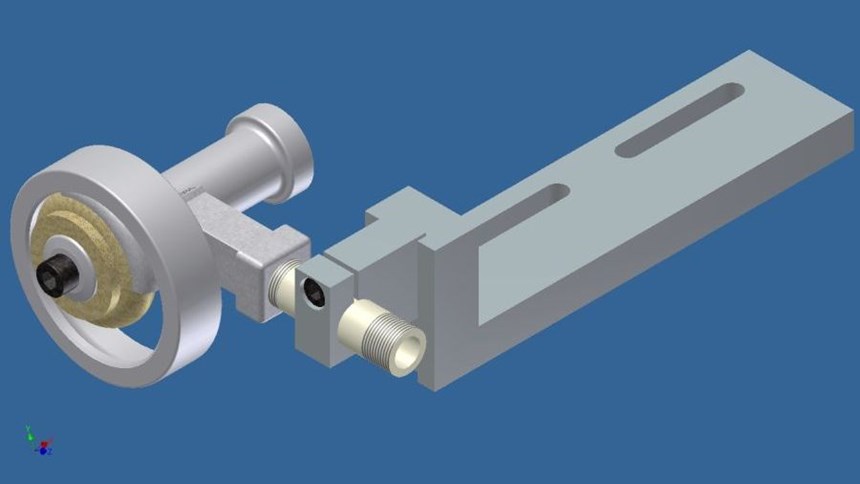

Grinding wheel maker Norton/Saint-Gobain wanted to learn if it really did have to accept this. The company fabricated compact nozzles slender enough to reach deep into the narrow space between the workpiece and wheel. Early nozzles were made through bending and welding metal, but these didn’t control the high-pressure flow adequately to direct it at the wheel. To achieve this control, the narrow nozzle would need contoured passages inside. The resulting design was too complex to fabricate, but the company was able to grow it in one piece using direct metal laser sintering (DMLS).

The nozzle made in this way is seen in the photo at top left. The illustration just beneath it shows how this nozzle reaches fully into the small space between the part and wheel. The image at the bottom shows the detail of the internal passages that direct the fluid.

Testing with this nozzle showed that it enabled finer ground surfaces and faster grinding times compared to standard nozzles. While additive manufacturing is often associated with a poor surface finish, here is a case where it delivered a finish improvement.

Learn more about this application at short.additivemanufacturing.media/idgrind.