Additive Manufacturing for Hard Tooling

Hybrid manufacturing is enabling tooling to be made with additive processes.

Last month I discussed the concept of hybrid manufacturing—combining additive manufacturing (AM) and subtractive machining together within a single machine to make parts more efficiently. This month, I want to touch on another form of hybrid manufacturing that AM is enabling, namely, making the tooling to make the part (versus making the part itself).

Numerous companies have been using polymer 3D printing for years to make fixtures and jigs to aid production and fabrication with conventional manufacturing methods. Some have even been using polymer 3D printed parts to make soft tooling. However, with metal AM, companies can now make hard tooling for injection molding, for instance, and that can be game changing.

Why use AM for hard tooling? The answer is simple: It provides design freedom, which is the same reason we’d use AM for making complex and intricate features and parts. The same goes for hard tooling. The design freedom can be used to create features that would be too expensive or impossible to make via conventional means like machining. The bigger bang for the buck, though, is printing conformal cooling channels inside the mold to help manage thermal cycles during production.

One of the factors that limits the speed of an injection molding process is mold temperature. The ability to dissipate heat quicker from a mold can lead to reductions of 10, 20 and even 40% in cycle time based on some of the studies that I have read. More importantly, the ability to control the mold temperature more accurately and exploit its interactions with melt temperature of the plastic being injected into the mold can reduce defects and lead to improved properties and enhance part performance. Who wouldn’t want a faster process and better parts?

Unfortunately, it’s not that easy. In October, I discussed the issues that you will encounter with surface roughness when using AM, and the same applies here. Horizontal and vertical faces will have different surface finishes, and conformal cooling channels will not be smooth either—they may even be filled with support structures if you aren’t careful in how you design and orient them. I would go so far as to say that none of today’s AM processes will give you anything close to the surface finish you need for hard tooling. Laser powder-bed fusion (PBF) may get you close in rare cases, but you have no chance with directed-energy deposition (DED) right now, regardless of the thermal energy source.

Luckily, this is where some of the hybrid manufacturing systems that I talked about last time excel. In fact, the hybrid PBF and subtractive systems offered by Matsuura and Sodick create finished molds in a single machine, and now DMG MORI is getting into the game.

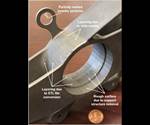

I had the pleasure of meeting with the team from Matsuura in our lab a couple of years ago, and the parts they showed me back then were impressive. As you can see in the image, there is no way you are going to get a smooth, finished surface like that from PBF alone. You can only do that with machining, and that’s exactly what their hybrid manufacturing system does. It adds a few layers to the part (in this case, the mold), then machines and finishes surfaces, then adds a few more layers, machines, and repeats until the mold is done. It’s a sight to behold, and I have yet to meet a machining expert who can tell me how to machine the curvy internal conformal cooling channels that are possible with this technology. If you have any ideas that you want to share, I’m all ears.

Meanwhile, if you specialize in making hard tooling for companies, I encourage you to keep an eye on this hybrid use of additive manufacturing. The molds that you can make with this technology are relatively small thus far, but that will change. Companies are actively working on larger PBF systems, and as hybrid machines gets better, people will soon start targeting large molds and dies with DED given the cost and lead time associated with that tooling as well.

Related Content

Sidus Space Successfully Launches LizzieSat Hybrid 3D-Printed Satellite

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

Read MoreNew Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read MoreJuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read MoreRead Next

Why Is My Surface So Rough?

Be aware of the inherent manufacturing and design challenges that impact the dimensions and tolerances that you can (or cannot) achieve on an “as built” part.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More