Prototyping

Renishaw RenAM 500Q Ultra AM System Features Productivity-Boosting Tempus Technology

The Tempus technology incorporates scanning algorithms that enable the laser to fire while the recoater is moving, saving up to nine seconds per build layer.

Read More3D Systems Develops C-103 Metal Alloy for Challenging Environments

This niobium alloy with hafnium and titanium alloying elements is resistant to decomposition by heat, pressure or chemical attack and thus retains its strength and form at high temperatures.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreOne Click Metal Partners With Select Additive to Expand US Presence

Together, the companies aim to deliver cutting-edge solutions, expert guidance and support to businesses seeking to harness the power of metal additive manufacturing.

Read MoreFarsoon FS350M-4 Metal AM System Offers Optimal Build Efficiency, Uniform Part Performance

The system is equipped with an advanced multilaser scanning strategy and calibration algorithms which can enable optimal build efficiency and uniformed part performance throughout the build area.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

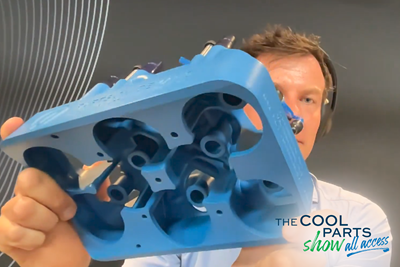

Watch3D Printing for Automated Food Packaging: The Cool Parts Show All Access

Parts on Demand CEO Neil van Es shows examples of 3D printed food automation hardware.

WatchAdditive Manufacturing for Defense: Targeting Qualification

Targeting qualification in additive manufacturing for the defense industry means ensuring repeatability as well as reliability as there is much at stake, including human lives. Certain requirements therefore must be met by weapons systems used by the defense industry.

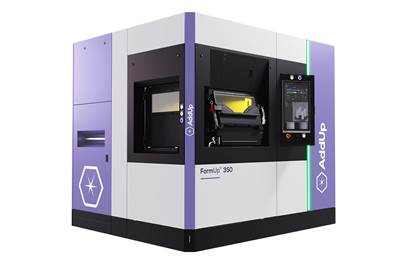

Read MoreAddUp, WBA Investigate Additive Manufacturing for Moldmaking Tooling Study

The additive manufacturing (AM) tooling study focused on six select companies, offering them the opportunity to test the introduction of AM and specifically implement the technical and economic advantages of AM technology for their injection molds.

Read More