Prototyping

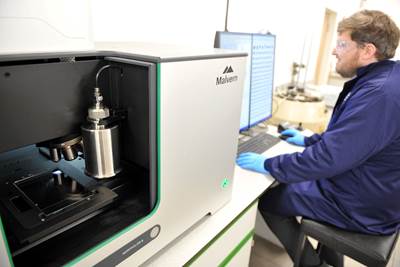

MPI Launches AI Project to Create Material Reuse Management Tool for Metal 3D Printing

MPI is working with Additive Manufacturing Solutions and AMFG to create a versatile, commercial predictive material reuse management tool that will enable additive manufacturing to expand by introducing greater cost efficiencies.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

WatchMore on 3D Printed Ducts: Optimizing for Airflow

Once air ducts transition to AM, the next step is using the physics of airflow to optimize the design.

Read MoreHow 3D Printers Will Change for Production: The Cool Parts Show All Access

As Eaton advances toward production of aircraft ducts now made via 3D printed composite instead of metal, a team member involved with this work considers the machine features that will make them more capable for this role.

Read MoreKBM Materials to Distribute Sandvik Metal Powders

The collaboration will increase accessibility of Sandvik’s Osprey metal powders, which includes premium titanium alloys and copper powder, as well as nickel-based superalloys, cobalt-chrome and ultrahard maraging steels.

Read MoreGuha Manogharan Named Co-Director of Penn State’s Additive Manufacturing Center

Penn State’s Center for Innovative Materials Processing through Direct Digital Deposition is an interdisciplinary research center that works to advance additive manufacturing and materials research.

Read MoreLithoz, ORNL Partner to Advance Processing for High-Temperature Ceramics

The new process could enable laser slurry drying of non-oxide ceramics with high refractive indexes

Read MoreMaking Sense of Qualification, Certification and Standards in Additive Manufacturing: AM Radio #48

AM needs standards and processes for qualification and certification just like any other process. In this conversation with Dr. Tim Simpson, AM editors dive into the distinctions between these terms, and explore how they are influencing additive adoption and advancement.

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreInsight Masterbatches Improve Appearance of PLA, PETG FDM Systems, and More News of Note

America Makes names winners of EARTH Project totaling $1.2 million | The Virtual Foundry developed its M300 Tool Steel Filamet material for fused filament fabrication, offering compatibility with a variety of 3D printers.

Read More