Prototyping

Digital Alloys Offers Joule Printing as a Service

Rapid 2019: Digital Alloys highlights Joule Printing, its metal 3D printing process that will be used to make parts for customers later this year.

Read MoreWhat Is Directed Energy Deposition?

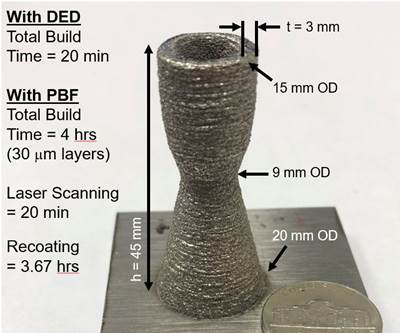

Analyzing directed energy deposition and powder-bed fusion provides a thorough understanding of the extra machining necessary for a “near-net shape” versus a “net shape” manufacturing process.

Read MoreSisma's Everes 3D Printers Limit Human Error

Rapid 2019: Sisma’s Everes Zero and Everes Uno digital light processing-based (DLP-based) 3D printers are said to be fast and accurate.

Read MoreHenkel, Origin Collaborate on Open Materials Platform

Henkel and Origin have partnered on Origin’s open materials platform to promote final parts production and the adoption of 3D printing technology.

Read MoreUltimaker S5 Desktop 3D Printer Enables Print Core Swap in Seconds

Rapid 2019: The Ultimaker S5 desktop 3D printer combines dual extrusion, advanced connectivity and an open filament system to make 3D printing accessible for more applications.

Read MoreXRize Desktop 3D Printer Provides Full-Color Parts

Rapid 2019: Rize’s XRize 3D desktop printer is designed to minimize processing and cleaning needs while manufacturing functional parts.

Read MoreProtolabs Metal 3D Printing Meets Demanding Part Requirements

Rapid 2019: Protolabs’ direct metal laser sintering (DMLS) process is designed for demanding applications.

Read MoreThermwood Hybrid Machine Produces Near-Net-Shape Parts

Rapid 2019: Thermwood’s Large Scale Additive Manufacturing (LSAM) system uses both 3D printing and machining to produce a near-net-shape product.

Read MoreVideo: Inside the Penn State Additive Manufacturing Master's Program, Part 4

Kevin White, mechanical engineer at the Naval Nuclear Lab and student at Penn State, shares how a higher education in AM provides benefits beyond technical training.

WatchDow, ECCO, Dassault Design 3D-Printed, Customizable Midsoles

Dow, ECCO and Dassault Systèmes have collaborated on a footwear customization project called Quant-U, that combines the customer’s individual biomechanical data, Silastic 3D 3335 liquid silicone rubber (LSR) from Dow and additive manufacturing (AM).

Read More