Prototyping

Video: How Simulation Assists Directed Energy Deposition

Scrapping an AM part is potentially as costly as scrapping a machined part. Directed energy deposition is an additive process that can benefit from a resource that safeguards machining: simulation software.

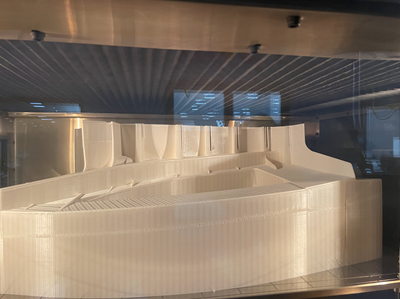

WatchWhat Is Material Extrusion 3D Printing?

Material extrusion extrudes material through a nozzle and selectively deposits it layer-by-layer to form an object. After three decades of material advancements and a diverse array of start-ups and applications, the use cases for this technology are still going strong.

WatchWebinar: Selecting Parts for Additive Manufacturing

Join the SLM Solutions webinar on August 14 to learn what parts, features and geometries are best suited for optimization with metal additive manufacturing and tips of what may make the process unfeasible.

Read MoreAmerica Makes Opens Third Satellite Center

America Makes has announced its third Satellite Center, located at the National Institute for Aviation Research (NIAR) on Witchita State University’s campus.

Read MoreVideo: What is Directed Energy Deposition?

DED is an additive manufacturing process that builds features or parts in metal by placing material where needed.

WatchRobot Is Production Solution for Laser Metal Deposition

The move from prototyping to production might involve a move from machine tool to robot, but development work between Formalloy and the robot suppliers means the process and programming do not have to change.

Read MoreSandvik Acquires Stake in Beam IT

Sandvik has acquired a stake in Beam IT, a deal expected to strengthen both companies’ position in the metal AM market.

Read More3D Systems Resin Produces Durable, Flexible Parts

3D Systems’ latest addition to its materials portfolio, FabPro Flexible BLK, produces tough 3D printed parts with the look and feel of molded polypropylene.

Read MoreHow 3D Printing Enables Sustainability in a High-Turnover Consumer Market

Pengraff UK built its business initially providing mounting solutions for routers and telecommunications equipment, hardware with built-in obsolescence. 3D printing and sustainable materials enable the company to live its values while manufacturing products with a limited lifespan.

Read MoreSnapmaker 2.0 Offers Filament Runout Recovery

The Snapmaker 2.0 comes in three sizes capable of 3D printing, laser engraving and CNC carving, all of which are features upgraded from the first Snapmaker model.

Read More