Prototyping

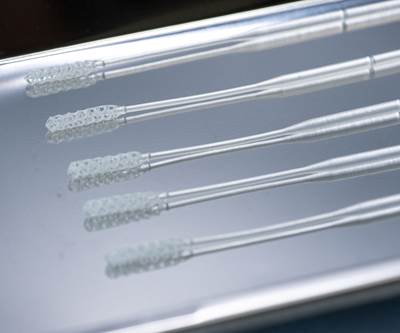

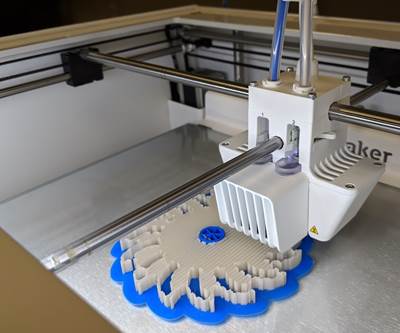

Consortium Aims to Print COVID-19 Test Swabs at Rate of Millions Per Week

Nasopharyngeal swabs are now available for order and immediate fulfillment through members of this consortium, including: Carbon, Formlabs, Envisiontec and Origin.

Read MoreDoes Asia's Low-Cost Manufacturing Option Still Make Sense?

As U.S.-based companies try to stay ahead of COVID-19, global supply chains are under renewed scrutiny. Are uncertainties and delays caused by global crises worth the short-term cost savings?

Read MoreA Hospital's Perspective: TriHealth Receives PPE with 3D Printed Components

A face shield solution developed by GE Additive is now in use at Cincinnati-area hospitals. A combination of 3D printed adapters and off-the-shelf shields and hard hats makes this PPE fully reusable.

Read MoreVelo3D Launches Large Format 3D Metal Printer with Knust-Godwin as First Customer

The next-generation Sapphire machine will print up to 1 meter in height, said to be the tallest laser-powder additive manufacturing system.

Read MoreThermwood's New LSAM Model Provides Both Print and Trim Heads

Thermwood’s LSAM MT is a lower cost moving table version of its industry-leading LSAM (large scale additive system).

Read More3D Printing and Coronavirus Check-In - Week of 4/13/2020

In this week's update we discuss how additive manufacturing is supporting injection molding for masks, and ramping up to production quantities of face shields and testing swabs.

WatchLubrizol’s Powder TPU for 3D Printing Passes Skin Sensitization Tests

Lubrizol Engineered Polymers’ Estane 3D TPU M95A powder TPU has passed skin sensitization and cytotoxicity tests in accordance with ISO 10993-5 and 10993-10.

Read MoreMakerBot LABS Extruder Transforms Method 3D Printer into an Open Materials Platform

BASF 3D Printing Solutions and LEHVOSS Group join other filament suppliers in the Method Materials Development Program.

Read MoreInert Gases: Easing the Challenges of Metal AM Operations

Inert Gases aid metal additive manufacturing processes but the usefulness for each process is dependent upon the gas used. Dive into three inert gases to learn more about how to use them in an additive capacity.

Read MoreA Circular Economy for 3D Printed Plastics Starts with Material

When the greatest share of a product’s environmental impact comes from producing its feedstock, selecting the right material is critical. For 3D printing and manufacturing in plastic, biopolymer could be the first step toward a more sustainable model.

Read More