Production

Finally, a Metal Additive Manufacturing System That’s Built for Production

For metal additive manufacturing to become a viable alternative in a production environment, it must have the process controls expected of other manufacturing processes. That technology has finally arrived.

Read MoreVideo: Periscope Case Shows 3D Printing for Niche Manufacturing

Manufacturing without mold tooling allows the production quantity to be tailored to the market size.

WatchHow Does Additive Manufacturing Complement Injection Molding?

The Additive Manufacturing Workshop for Plastics, held during Amerimold 2019, offered a platform for industry experts and mold builders to discuss how AM can complement injection molding and what it takes to transition from prototyping to high-volume production.

Read MoreHP Opens Barcelona 3D Printing and Digital Manufacturing Center of Excellence

HP has opened the doors of its 3D Printing and Digital Manufacturing Center of Excellence in Barcelona, Spain, expected to accelerate transformation of industries with R&D, engineering, co-development and sustainable innovation.

Read MoreNXT Factory Unveils Quantum Laser Sintering System

NXT Factory has unveiled the final version of the QLS 350, a powder-based additive manufacturing (AM) quantum laser sintering system designed for low and medium volume production for the injection molding industry.

Read MoreIncodema3D Reaches the Tipping Point for Production Additive Manufacturing

The New York manufacturer is launching into its first continuous flow production job for metal AM. Owner and CEO Sean Whittaker shares what it took to arrive here.

Read MoreLinear Motor Platform Delivers Speed, Low Part Cost for Production AM

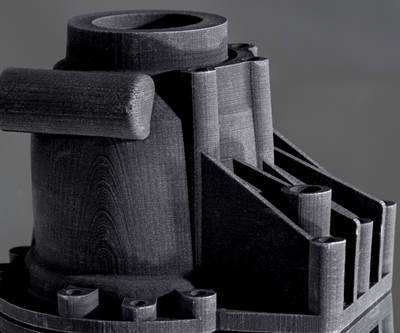

Essentium’s additive manufacturing machine based on semiconductor manufacturing has as much in common with precision machine tools as with other FFF 3D printers.

WatchHP's Multi Jet Fusion 5200 Series Enables Production

HP’s Multi Jet Fusion (MJF) 5200 series combines systems, data intelligence, software, services and materials innovations, enabling customers to scale 3D production and target business growth.

Read MoreWebinar: 5 Attributes to Consider for AM Production

Evolve will look at five keys areas required by organization for additive to sit on the manufacturing floor right next to their injection molding production lines – materials, speed, quality, scalability and cost. They will also provide a peek under the hood of Evolve Additive’s new STEP technology.

Read MoreMarkforged Unveils AI-Powered Blacksmith

Markforged has announced its AI-powered platform, Blacksmith, designed to enable manufacturing equipment to reprogram itself to make perfect parts.

Read More

.jpg;maxWidth=400;quality=70)