America Makes Offers Additive Manufacturing Research Grants Worth Nearly $12 Million

This project call for additive manufacturing research projects offers the largest funding opportunity launched by America Makes since its inception in 2012.

The National Center for Defense Manufacturing and Machining (NCDMM) and America Makes have announced two new open project calls funded by the Office of the Under Secretary of Defense, Research and Engineering Manufacturing Technology Office (OSD (R&E)), and the Air Force Research Laboratory (AFRL) worth a total of $11.75 million. This is the largest funding opportunity launched by America Makes since its inception in 2012.

Each project call has two areas of focus. One award is anticipated for each topic area with the maximum request for funding varying depending upon the topic being addressed.

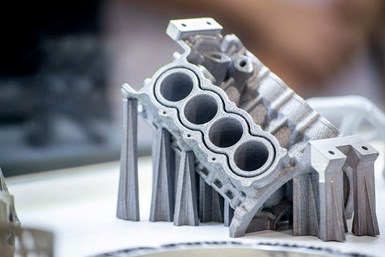

The first project call for “Powder Alloy Development for Additive Manufacturing (PADAM)” is worth $6 million and is being funded by the AFRL. America Makes, its members and government stakeholders have assessed the benefits and strategic opportunities offered through the development and scaling of novel additive manufacturing (AM) materials at the Alloy Development Workshop in 2021. This project call aims to accelerate the maturation of AM high-temperature metals to demonstrate measurable improvement in application-specific performance criteria.

The PADAM request for proposal (RFP) is separated into two topic areas:

- Topic 1: High-Temperature Refractory Alloys ($3.6 million); and

- Topic 2: High-Temperature Nickel-Based Superalloys ($2.4 million)

“For the better part of a decade, the additive community has been advocating for funding to direct research and development to establish proven methods for applying the best attributes of novel AM materials. The materials that project partners will be working with are incredibly important to the future of the applications used in the aerospace and defense communities,” says Brandon Ribic, America Makes technology director. “Our organization is incredibly fortunate to have the support of the Under Secretary of Defense and AFRL, and the engagement of the brightest minds in the country who will be collaborating to revolutionize this technology.”

The second project call is for “Proliferation of AM Material Datasets” and offers a total of $5.75 million in funding through OSD(R&E) and the AFRL. Recognizing there are additional material systems beyond Ti-6Al-4V that can benefit the AM industry, this project call aims to increase the number and type of pedigreed, statistically-based and industrially-relevant AM material datasets. The RFP also looks to encourage the proliferation of these learnings, practices and data to a more expansive cross section of the AM supply chain by requiring partnerships with small businesses.

The Proliferation of AM Material Datasets RFP is separated into two topic areas:

- Topic 1: Aluminum Alloy Material Dataset ($2.875 million)

- Topic 2: High-Temperature Nick-Based Superalloys ($2.875 million)

“This project is a great opportunity for America Makes and our members to lay the foundation for ground-breaking development and incorporation of alloy-based refractory metals, which are extraordinarily resistant to heat and wear, into AM applications used in the aerospace, defense and energy industries,” says John Martin, America Makes additive manufacturing research director. “Additionally, data and best practices formulated and shared as a result of this project will help expand the AM supply chain through the inclusion of smaller businesses from across the country.”

- Membership Eligibility Deadline is Sept. 14

- Submission Deadline is Sept. 29 by 5 p.m., ET

- Anticipated Awards Announcement is Oct. 30

Proposers for the project calls are advised to reference the RFP for full details and guidelines:

Related Content

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More