Implants

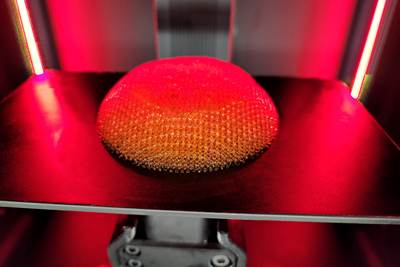

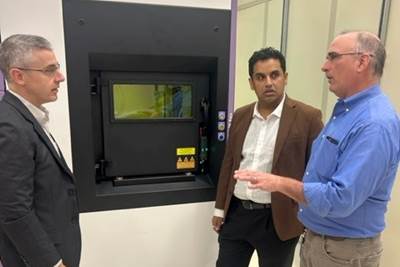

Stratasys, CollPlant Unite Technologies for Industrial-Scale Bioprinting of Tissues, Organs

The joint development and commercialization agreement will initially focus on development of a bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity.

Read MoreMore Affordable Suture Anchors 3D Printed from PEKK: The Cool Parts Show #60

Selective laser sintering (SLS) of polyether ketone ketone (PEKK) is being used to produce medical implants that are more cost effective and perform better than their conventional counterparts. We highlight fasteners known as suture anchors in this episode of The Cool Parts Show.

Watch3D Systems Developing Regenerative Tissue Program for Surgical Reconstruction

The first product under development targets patient-specific regenerative breast tissue.

Read MoreNexa3D Dental Resins, Workflow Increase Throughput

Nexa3D’s growing dental resin portfolio now includes 10 validated materials for both the NXD series and the XiP printer platforms.

Read MoreAmnovis Simplifies Regulatory Submission for 3D Printed Titanium Implants

Amnovis has incorporated its additive manufacturing process expertise and experience with titanium 3D printing into an FDA Master File to help facilitate customers’ regulatory submissions for 3D printed titanium implants.

Read MoreFormlabs Dental Offers Solutions for Making Digital Dentistry Easier

Formlabs’ dental offerings enable dental labs and practices to reduce costs and increase efficiency, while delivering industry-leading print quality.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreNMPA Certifies Farsoon 3D Printed Tantalum Interspinal Fusion Cage

The company says the additively manufactured implants can be fully customized according to patients’ conditions, and the trabecular microstructure can achieve a high porosity of 68-78% to promote bone tissue and vessel fusion.

Read MoreProduction AM Demands Process and Procedures — More Machines Will Come Later

Arch Additive has transitioned to full production of implants made through electron beam melting. The transition has involved practices and personnel, not equipment. As customer products win approval and go to market, here are 5 operational moves the AM implant manufacturer has made.

Read MorePrinterPrezz/Vertex Manufacturing Rebrands to Zeda

The rebranding is said to reflect the company’s “Z to A” approach, which means it starts first with the customer in mind and ends with a product.

Read More