Stratasys, CollPlant Unite Technologies for Industrial-Scale Bioprinting of Tissues, Organs

The joint development and commercialization agreement will initially focus on development of a bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity.

Share

Read Next

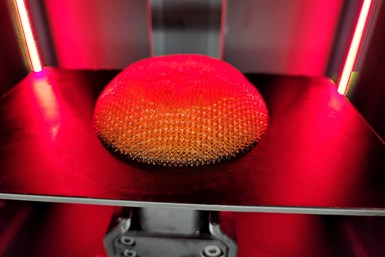

Stratasys and CollPlant Biotechnologies are collaborating on the development of a solution for bio-fabrication human tissues and organs using Stratasys’ P3 technology-based bioprinter and CollPlant’s rh-Collagen-based bioinks. The first project focuses on the development of an industrial-scale solution for CollPlant’s regenerative breast implants program.

Stratasys will provide its expertise in polymer 3D printing solutions for CollPlant, which is a regenerative and aesthetics medicine company developing technologies and products based on its plant-based collagen for tissue regeneration and organ manufacturing.

The bioprinter is based on Stratasys’ precise P3 3D printing technology in combination with CollPlant's flagship bioinks. The printer will enable the production of CollPlant’s breast implants, which are being designed to regenerate an individual’s natural breast tissue without eliciting immune response, providing a potentially revolutionary alternative for both aesthetic and reconstructive procedures.

Currently, the global breast implant market is estimated to be $2.6 billion, with breast reconstruction and augmentation procedures representing the second most common plastic surgery procedure performed worldwide. The most common breast augmentation or reconstruction procedures today are based on synthetic silicone breast implantations, which is an artificial substitution for natural regenerated tissue and has risks of complications.

As part of the collaboration, both companies have agreed to cross-promote each other’s bioprinting products. Stratasys’s bioprinter will be offered to customers together with CollPlant’s bioinks and, similarly, Stratasys’ bioprinter will be offered to CollPlant’s business partners and customers.

“Through this partnership with CollPlant, we have an important opportunity to transform health care with bioprinting to improve the lives of patients undergoing breast augmentation or reconstruction procedures,” says Stratasys CEO Dr. Yoav Zeif. “This agreement is well aligned with our strategy to deliver complete solutions for high-growth industry applications with our ecosystem of partners, and the production scale and precision 3D printing capabilities of Stratasys’ P3 Programmable Photopolymerization technology are a particularly strong fit for bioprinting applications.”

The partnership is focused on accelerating the industrialization of bioprinting for regenerative medicine. “Stratasys is leading in additive manufacturing and we are excited to collaborate ith them on this transformative initiative,” says Yehiel Tal, CollPlant CEO. “The P3 technology allows printing with high resolution and process control, and we believe that the combined, pioneering technologies of both companies will streamline the development and production process so that we have the most efficient means to produce our regenerative breast implants, and other potential tissues and organs. We believe that our rhCollagen-based regenerative implant has the potential to overcome the challenges of existing breast procedures that use silicone implants or autologous fat tissue transfer.”

In January 2023, CollPlant announced that it successfully completed a large-animal study for its 3D bioprinted regenerative breast implants. The preclinical study demonstrated progressive stages of tissue regeneration after three months, as highlighted by the formation of maturing connective tissue and neovascular networks within the implants, with no adverse events reported. Based on these positive results, CollPlant is planning to initiate a followup, large-animal study in the second half of 2023 using commercial-size implants to support subsequent human studies and future product commercialization.

- Read about the Stratasys partnership with Ricoh for print-on-demand medical models. This offering gives clinicians and patients increased access to patient-specific, 3D printed models for pre-operative surgical planning, diagnostic use and surgical education to improve clinical outcomes and drive significant savings through improved productivity.

- Learn how Stratasys’ innovation extends to moviemaking for 3D printed camera components used to capture “Avatar: The Way of Water” film. SNL Creative used AM materials from Stratasys and other providers to create stereoscopic camera rigs used by the production team during the creation of the new Avatar film. The custom-designed camera components met the rigorous requirements for filming and offered a modernized alternative for future film usage.

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More