Composites

Eight-Axis Robotic System Prints Composite Parts

This concept machine leverages robotics to 3D print in eight axes.

Read More7 Important Implications of the New Stratasys Production Demonstrators

One working machine concept expands the build size and speed for FDM. Another performs robotic 3D printing in composite material. Here is what these two concepts suggest about the advance of additive manufacturing into industrial production.

WatchUsing 3D Printing for Composite Molds and Tools: The Trend Continues

3D printing is becoming more common in the aerospace tooling realm. Production tooling can be made quickly and on-demand, which helps the tooling industry keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read More3D Printing Autoclavable Composite Molds

A polymer AM research team at ORNL reports it has successfully fabricated autoclave-capable carbon fiber composite molds, manufactured using large-scale 3D printing/additive manufacturing.

Read MoreFDM Enables “Smarter” Layup Tools

Building layup tools for composites via FDM eliminates some postprocessing and assembly steps, opening the door to more innovative designs.

Read MoreVideo: Toolingless Manufacturing and the Impact of Additive on Automotive Production

Jay Rogers of Local Motors discusses his company’s coming 3D-printed car and what it represents.

WatchAdditive Manufacturing with Composites at Carbon Fiber 2015

A cofounder of Arevo Labs will give a presentation on 3D printing with carbon fiber-reinforced polymers.

WatchDevelopmental LSAM Machine Adds Melt Shaping Capability

Development continues on Thermwood’s Large Scale Additive Manufacturing (LSAM) machine with the inclusion of a shaping wheel and plans for subtractive integration.

Read MoreWater Wash Out Tooling Process Developed

ExOne has qualified a new application for its 3D printing technology.

Read MorePrecision Without Deposition

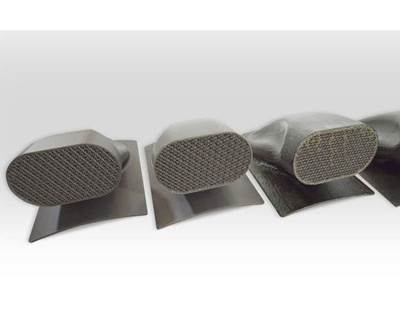

Is it possible to 3D print with carbon fiber fabric? It is, except that “printing” is not the right word. This additive process builds parts by stacking the carbon fiber sheets. The result is composite parts that don’t need tooling—but are strong enough that they could be used as tooling.

Read More