Automation

7 Important Implications of the New Stratasys Production Demonstrators

One working machine concept expands the build size and speed for FDM. Another performs robotic 3D printing in composite material. Here is what these two concepts suggest about the advance of additive manufacturing into industrial production.

WatchSelective Laser Sintering Cuts Lead Time for Clamping Unit Assembly

Industrial automation provider Comau redesigned a three-part clamping assembly for additive manufacturing, realizing benefits in lead time and waste.

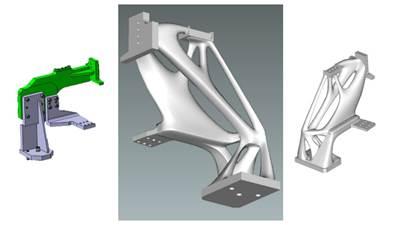

Read MoreSLM Achieves Weight Reduction for Robot Actuator

Selective laser melting made it possible to create a lighter, better performing actuator for a quadruped robot.

Read MoreAM System Using TIG Welding and Robot Relies on Flexible Enclosure for Gas Protection

The WAAM system has demonstrated the ability to produce a titanium aircraft part, but titanium in particular requires protection against oxidation.

Read MoreLaser-Sintered Grippers Solve Robotic Packing Challenges

Additive manufacturing produced lighter, stronger vacuum grippers for robots on a food packaging line.

Read MoreMachine Shop Turns to Additive for In-House Safety Covers and More

After purchasing a 3D printer to solve a safety issue, turning shop Swiss Automation has found many more applications for the additive manufacturing technology on its shop floor.

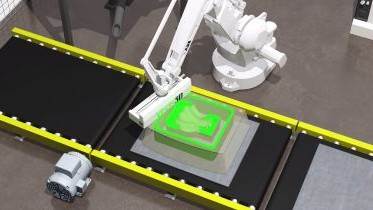

Read MoreVideo: Additive Manufacturing Robot for Foundry Molds

In addition to making either metal or plastic parts, one other production application of additive manufacturing is building in sand to create molds for casting without any need for a pattern.

WatchRenishaw to Introduce Additive Manufacturing System Aimed at Production

The first machine developed in-house by the company features a high-power laser and automation for industrial production via additive manufacturing.

Read More