Laser-Sintered Grippers Solve Robotic Packing Challenges

Additive manufacturing produced lighter, stronger vacuum grippers for robots on a food packaging line.

New robots for the customer’s pick-n-pack line were already on order when Langen Group, equipment supplier to the major U.S. food producer, began designing the end-of-arm tooling that would enable the robots to pick up wrapped, stacked crackers and place them into cardboard boxes. The engineers soon discovered a challenge: To maximize speed without upsetting the robots’ center of gravity, the combined weight of the tool and the product could be no more than 2 kilograms. Because the largest load of crackers was a 10-pack weighing 1.5 kilograms, end-of-arm tooling could weigh no more than 500 grams.

Langen turned to Anubis 3D, a division of Anubis Manufacturing Consultants Corp., for support. Using laser sintering technology from EOS, Anubis was able to design and manufacture end-of-arm tooling that fit within the weight restrictions for the robots and performed with better gripping force than legacy grippers.

Anubis is an engineering and design consultancy firm based in Mississauga, Ontario, founded by Tharwat Fouad in 2005. Its main markets include the food and beverage, chemical, powder handling, and plastics manufacturing industries. The Anubis 3D division specializes in low-volume additive manufacturing (AM) of parts that are either too expensive, too complex or outright impossible to make through conventional manufacturing techniques.

The division currently owns three additive manufacturing machines from EOS, including an EOSINT P 395. This powder-bed laser sintering system uses a 50-watt CO2 laser to quickly and accurate “grow” parts from thermoplastic. The machine can build parts measuring as large as 340 by 340 by 620 mm with layer thicknesses ranging from 0.06 to 0.18 mm.

Since establishing this division, Anubis has designed a number of laser-sintered tools for injection molding and bottle packaging customers, as well as various brackets and supports. When Langen came to Anubis with the robot tooling challenge, Fouad knew that additive manufacturing could provide a solution.

In addition to weighing less than half a kilogram, the robot grippers for the pick-and-pack line had to be able to handle multiple package shapes and sizes. The food producer wanted a single tool that could handle three boxes sizes in two different configurations. The tool also needed to be quick-release and quick-connect so operators could change from one size to another without bolts and nuts that would add assembly time.

“Meeting these requirements would have been impossible with aluminum and sheet metal,” says Fouad. “To handle a heavier metal tool they’d have to reorder larger robots, which would have been more expensive—and they were also under extreme time constraints.”

Instead of a more traditional metal vacuum plate and shroud, Anubis created a lighter, streamlined set of components to be made on its EOSINT P 395 machine. The parts were designed specifically for AM using SolidThinking's Inspire software to optimize the design of the structures organically, following the lines of the geometry and adjusting the thickness as needed for strength and/or flexibility. Finite Element Analysis (FEA) is built into the optimization to analyze stresses and strains on the structure.

The material used for the main vacuum part was nylon 12 (PA 2200 material from EOS), chosen for its flexibility and ability to sustain crash loads, and because it is certified as USP Class VI approved for food contact. Anubis loaded the material properties and vacuum requirements into the software, then used those calculations to determine how many and what size holes should be placed in the vacuum cup.

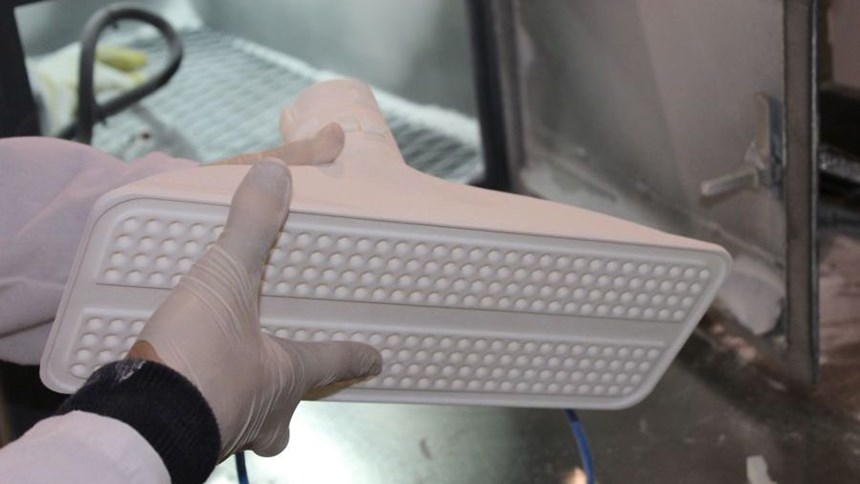

“The options we looked at were whether to have fewer but larger holes, or more, smaller ones,” says Fouad. First the Anubis team duplicated the traditional aluminum plate hole layout using nylon 12 in the EOSINT P 395 system and tested the gripping power of the result. Then, to further increase the grip, they created a new design with profiled holes and channels that could not have been manufactured conventionally.

The team found that the second design, with a larger number of smaller holes laid out in a Swiss cheese pattern of channels leading to the primary vacuum hole at the top of the workpiece, created a superior grip on the cracker stacks, providing four times the gripping force of legacy vacuum grippers. Compared to similar machined designs, the laser-sintered version uses less air but has greater picking power.

“The efficiency of the new hole profile we developed with EOS technology enabled the redesigned gripper to suction so well you could actually hang on it with your own weight,” says Fouad.

In contrast to a more traditional vacuum plate and shroud, which would have taken months to design and manufacture, Anubis took only a week to additively manufacture, assemble and test the new lightweight tool. After a light bead blasting, the laser-sintered parts were dyed per customer specifications and assembled with the mounting pieces. The vacuum grippers were delivered to Langen Group and installed on the newly arrived robots at the food producer’s plant.

“To design and produce tooling capable of picking what we wanted while still staying within the payload constraints of the robot would have been impossible before,” says Robert Husnik, Langen Group engineering manager. “Due to the freedom provided by plastics laser-sintering, we can now do the impossible.”

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read More6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)