Xuron Hand Tools Cut Filament Flat, Remove Supports

Ergonomic hand tools for fused filament fabrication-style 3D printers include micro-shear to cut filament for feeding and pliers for removing postprinting supports.

Share

Read Next

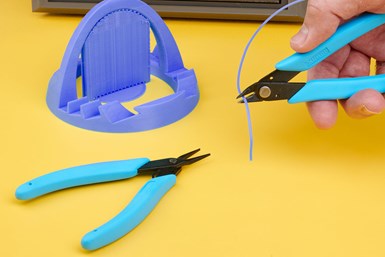

Xuron Model 450 Tweezer-Nose Pliers and Model 170-II Micro-Shear Flush Cutter for AM.

Xuron pairs two hand tools for fused filament fabrication-style 3D printers to cut the filament for feeding and for removing postprinting supports.

The Xuron Model 170-II Micro-Shear Flush Cutter produces a clean, square cut using shear action for trimming filament and cleaning up printed parts. It is ergonomically sized and shaped to fit comfortably in the hand, while its ultraslim profile increases access into high-density areas.

Xuron’s Model 450 Tweezer-Nose Pliers is an ultra-precise needle nose plier capable of grasping and holding wire less than 1 mm thick with the strength for wire forming. The tool is strong and durable with precison-tip alignment and radiused edges to protect wire.

Both tools are ergonomically designed, and have contoured, nonslip soft rubber grips and a light touch return spring. Made from alloyed steel and hardened for high reliability and long life, these tools have a glare-eliminating black finish.

Related Content

-

6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

FDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.