Wayland Additive’s Calibur3 Features NeuBeam PBF Process

Formnext 2023: The company’s fully neutralized NeuBeam process for the Calibur3 metal additive manufacturing system solves the charging issues that have previously restricted electron beam melting processes.

Share

Read Next

Wayland Additive’s Calibur3 metal additive manufacturing (AM) system was developed to overcome common problems with metal AM and deliver on all of the advantages of metal electron beam (eBeam) powder bed fusion (PBF) technology.

The company’s fully neutralized NeuBeam process for the Calibur3 solves the charging issues that have, until now, restricted EBM processes. The open nature of this metal AM system also offers the ability to process a wider palette of metal materials.

“As we champion the wider adoption of metal AM throughout industry, our focus on extending the material range available to companies is fundamental,” says Will Richardson, Wayland CEO. “NeuBeam unlocks a swathe of complex metal production opportunities that current metal AM processes struggle with. This is because the process is compatible with a much wider range of metal powders, including but not limited to refractory metals and highly reflective alloys.”

NeuBeam has the ability to process existing metal materials, which reduces the difficulities related to qualifying new parts. The fact that NeuBeam achieves full charge neutralization during the build process is the key to offering superior metallurgical capabilities, and opens up the choice of a wider palette of materials for metal AM.

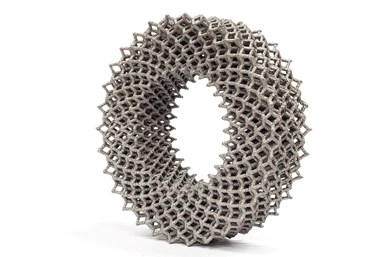

The process also eliminates issues concerning residual stress typical with alternative metal AM processes, and produces fully dense parts with demonstrably greater internal integrity. NeuBeam also removes the need for an entire sinter cake around the parts, which requires costly and time-consuming postprocessing steps that can negate the benefits of AM for a given application. This is achieved by only applying the required high temperatures to the part being built, rather than the entire powder bed.

“The elimination of residual stresses is a huge opportunity for the accelerated uptake of metal AM across a whole array of industry applications,” Richardson adds. “It is fundamentally because of the fact that the process is what we call a ‘hot part’ rather than a ‘hot bed’ process. This means that the high processing temperatures required are applied to the part, not the bed, and this ensures free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption.”

Examples include intricate large parts made from titanium (which when processed using NeuBeam require no postprocess heat treatment); carbon steels (the NeuBeam process enabling the printing of alloys with higher carbon contents that would otherwise crack when printed using existing laser PBF techniques); and fully dense parts in Tungsten (a refractory metal that requires exceptionally high temperatures to melt and which his prone to cracking in any other metal AM process). The capabilities of NeuBeam means that users can tackle a much broader spectrum of metal materials and develop them for Calibur3, and can do it rapidly.

The core feature of the Calibur3 system is in its neutralizing the unstable nature of the eBeam process, an issue that Wayland says it has fully resolved. In addition, Calibur3 is modular in design with a well-thought-out user interface that is easy to use. The machine is also supplied with a Depowdering and Recycling (DPR) unit.

- Learn more about Wayland Additive’s Calibur3 for geometrically complex metal parts. The NeuBeam technology is a hot part process rather than a hot bed process. That means it can efficiently create parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed.

- Read about NeuBeam 3D printing process for electron beam melting which overcomes the challenges in bringing new materials and capabilities to EBM metal 3D printing.

Related Content

MoldJet Technology Enables High-Throughput Metal, Ceramic Additive Manufacturing

Formnext 2023: Tritone Technologies’ additive manufacturing solutions enable industrial throughput of accurate parts with a range of metal and ceramic materials.

Read MoreTrinkle Additive App Suite Features Collection of Accessible, Intuitive Design Apps

Formnext 2024: The Additive App Suite builds on the success of the company’s fixturemate — a user-friendly design app for creating fixtures. The software includes three new apps with more to come.

Read MoreWhat We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More