nTopology 3.0 Speeds Advanced AM Engineering Design

New opt-in feature enables nTop users to experience an instant 10 to to 100 times performance boost when visualizing workflows that use complex field-driven geometry.

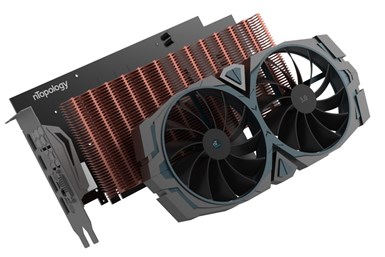

With GPU acceleration, interacting with complex designs in nTopology becomes seamless.

The nTopology 3.0 was developed to provide faster advanced engineering design. This software release introduces real-time visualization with GPU acceleration, offering a technology breakthrough that can fundamentally change how nTop users interact with the software.

The GPU acceleration provides seamless interactivity, the company says. By enabling this new opt-in feature, nTop users can experience an instant 10 to to 100 times performance boost when visualizing workflows that use complex field-driven geometry. Users will be able to preview design changes in real-time and regenerate parts with even the most complex geometry in seconds.

The nTopology 3.0 also consolidates recent incremental technology improvements to the software. These include functional latticing workflows, industry-leading topology optimization tools, expanded engineering simulation utilities and advanced design automation capabilities.

At the core of nTopology lies its implicit modeling engine for breakthrough performance with gpu acceleration. In implicit modeling, every solid body is described by a single mathematical equation. This representation enables users to generate even the most complex part geometry reliably and error-free.

Any CPU can evaluate this implicit equation in milliseconds. With GPU acceleration, interacting with complex designs in nTopology becomes seamless, enhancing the connection between the designer and the software. The software can now utilize both the CPU and GPU of a user’s system, unlocking a 10 to 100 times performance increase. As a result, latticing, texturing, filleting, shelling and other field-driven operations can now be previewed in real-time. Even the most complex designs are rebuilt in a few seconds.

Related Content

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

-

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

-

7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.