Kennametal KAR85-AM-K is Corrosion-Resistant Tungsten Carbide for Additive Manufacturing

KAR85-AM-K is said to combine the wear performance of conventional tungsten carbide with the design flexibility of 3D printing to produce high-performance parts for oil and gas, power generation and more.

Share

Read Next

KAR85-AM-K is available exclusively in combination with Kennametal’s binder jet 3D printing capabilities to produce fully finished wear components.

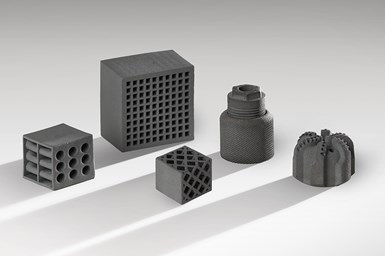

Kennametal’s KAR85-AM-K is its most corrosion-resistant tungsten carbide grade for metal additive manufacturing (AM). It is available exclusively in combination with Kennametal’s binder jet 3D printing capabilities to produce fully finished wear components.

With KAR85-AM-K, Kennametal combines the advantages of 3D printing — such as greater design flexibility and shorter lead times — with the performance of conventional carbide to produce high-performance parts for customers in oil and gas, power generation and more. Components made with the new grade are already in field trials with select customers.

Drawing on its deep materials science expertise, the company says it developed KAR85-AM-K to provide corrosion- and wear-resistant properties analogous to its conventional counterpart grade, CN13S. Combined with Kennametal’s binder jet AM capabilities, KAR85-AM-K is said to result in fully densified, corrosion-resistant components that meet or exceed the properties of conventionally manufactured carbide components.

The new grade composition features a proprietary blend of cobalt, nickel and chromium for improved corrosion resistance compared to standard cobalt-based tungsten grades. It is Kennametal’s second commercial carbide grade developed for use in its binder jetting AM processes and the latest addition to the business’s portfolio of high-performance metal powders optimized for 3D printing.

Kennametal Additive Manufacturing, the company’s 3D printing business unit within its Infrastructure segment, offers comprehensive 3D printing solutions, from raw material to finished part. The business develops carbide, cobalt, nickel and iron powders, including Stellite alloys, optimized for specific AM processes. At Kennametal’s research and development, prototyping and production center in Latrobe, Pennsylvania, the business utilizes laser powder bed and binder jet printing technologies, combined with post-print processing capabilities, to produce fully finished components for customers.

Related Content

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

-

Advancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

-

BPMI Chooses Velo3D Metal 3D Printing System to Produce Parts for U.S. Naval Nuclear Propulsion Program

The fully integrated 3D printing solution will be operated by ATI in a newly established facility that will provide the U.S. Naval Nuclear Propulsion Program with alternatives to cast parts.