Jabil’s PLA 3110P Is Bio-Based Alternative to Petrochemical-Based Powders

The engineered material can advance sustainability initiatives while providing a low-carbon alternative to nylon-based materials.

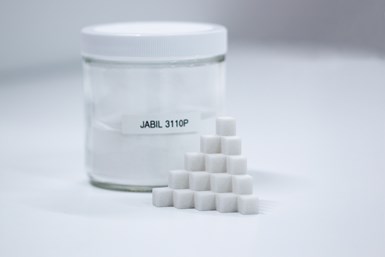

Jabil PLA 3110P, based on NatureWorks’ Ingeo PLA-based powder, is said to offer an 89% smaller carbon footprint compared to PA 12 when used in powder-bed fusion technologies. Photo Credit: Jabil

Jabil’s PLA 3110P is a novel powder based on a renewably sourced biomaterial that offers a bio-based alternative to petrochemical-based powders, such as Nylon-12 (PA 12). Developed in collaboration with NatureWorks — a manufacturer of polylactic acid (PLA) biopolymers —Jabil says its PLA 3110P material is made with NatureWorks Ingeo PLA and leverages Jabil’s “beaker-to-box” material innovations to deliver the first-ever PLA-based powder optimized for powder bed fusion technologies.

“Breakthroughs in material innovations are being driven by the need for better performing polymers,” says Luke Rodgers, senior director of R&D for additive manufacturing at Jabil. “We applied advanced morphology control to produce this sustainable and bio-based powder based on NatureWorks’ Ingeo biopolymer. Together, we are enabling an entirely new class of PLA material for the growing ecosystem of open additive manufacturing platforms.”

Jabil and NatureWorks collaborated to create, test and validate the PLA 3110P powder by combining NatureWorks’ expertise in PLA technologies with Jabil’s experience in developing polymer formulations, novel compounds and material system integration. As a result, the engineered material can advance sustainability initiatives while providing a low-carbon alternative to nylon-based materials.

“We are excited to join Jabil in launching the first Ingeo-based powder for open selective laser sintering (SLS) printing platforms,” said Salvador Ortega, global industry manager for NatureWorks. “Our Ingeo material is a lower-cost alternative with a carbon footprint that is 89% smaller than PA 12, which makes it well suited for a wide variety of additive manufacturing applications.”

NatureWorks says its Ingeo biopolymer helps convert atmospheric carbon dioxide into new performance powder, resulting in a smaller carbon footprint than incumbent materials. According to the companies, the material offers 89% smaller carbon footprint compared to PA 12 when used in powder-bed fusion technologies, according to Jabil.

The companies also say the materials is the first to market PLA-based powder to fulfill the need for general prototyping, thermoforming and compression fabrication, such as dental molds. The PLA 3110P material now gives customers more material choices for making prototypes as well as manufacturing brackets, jigs, fixtures and tooling. Moreover, the new PLA powder is an eco-friendly option for producing the precision geometries needed for thermoforming and compression molds, including custom dental impressions.

According to research firm SmarTech Analysis, polymer additive manufacturing technologies are forecasted to move into a multitude of industries over the next decade, with print production growing to nearly $26 billion annually by 2030.

Jabil says it continually applies polymer science advancements to elevate commodity resins with value-added attributes. Over the past two years, Jabil has introduced several materials, including PA 0600, which provides the high strength and stiffness associated with Delrin or alternative POM materials without the risk of exposure to formaldehyde emissions when the material is overheated.

In 2022, Jabil released PK 5000 which features high-impact strength, high-abrasion resistance and improved elongation over other nylon materials. The polyketone resin used to make PK 5000 is an eco-friendly, low-carbon material made from carbon monoxide, which can further reduce carbon footprints.

- Learn about Jabil’s PK 5000 material that was developed for improved strength and chemical resistance. The engineered material is said to offer high barrier properties and low-moisture absorption, which may be critical for ensuring the quality and resilience of certain parts and products exposed to fuel and water.

- Read about the Titan and Jabil partnership that customizes formulations for pellet extrusion 3D Printing. The partnership qualifies and integrates customized materials for use on Titan’s pellet-based Atlas 3D printers to produce stronger, lighter and more flexible parts.

Related Content

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreVideo: A Mechanical Method for Metal Powder Production

Metal Powder Works has developed a method for producing powders from solid barstock, no melting required. This video covers how the process works and benefits of mechanical production of powders.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More