HP Universal Build Manager Optimizes, Automates Workflows

The software platform reimagines digital workflows by enabling personalization and end-to-end control across multiple additive manufacturing technologies.

Share

Read Next

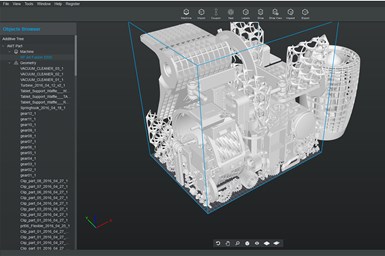

HP Universal Build Manager Powered by Dyndrite

HP Universal Build Manager Powered by Dyndrite is designed to bring increased productivity and efficiency as well as automation to additive build management for 3D printing processes. The software platform reimagines digital workflows by enabling personalization and end-to-end control across multiple additive manufacturing (AM) technologies. The solution has been designed to improve the additive technician’s efficiency, productivity and quality, enabling mass personalization, complex workflow automation, and scalability and extensibility in both manual drive and automated workflows.

“Automation, software and data are key to delivering mass customization of parts and unlocking the full potential of large-scale additive manufacturing,” says Ramon Pastor, general manager and global head of 3D printing and digital manufacturing, HP Inc. “We are committed to relentlessly improving our capabilities and helping customers optimize and automate workflows, enable compelling new applications and produce sustainable, high quality parts at scale.”

The platform is said to enables customers to simplify and automate build preparation across AM technologies at faster speeds. The software supports a variety of multiplatform additive workflows, including HP Multi Jet Fusion, Binder Jetting, Laser Powder Bed Fusion (LPBF), Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Selective Heat Sintering (SHS), Electron Beam Melting (EBM), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Stereolithography (SLA), Digital Light Projector (DLP), Laminated Object Manufacturing (LOM) and Composite-based Additive Manufacturing (CBAM).

Cobra Aero and Cobra Moto — companies specializing in the design and manufacture of propulsion systems for racing, firefighting, aerospace and surface and underwater vehicles — are deploying the HP Universal Build Manager to simplify and automate workflows across HP Jet Fusion and Renishaw AM systems.

“We are committed to producing the highest quality, most precise engine technology across all of our businesses,” says Sean Hilbert, president, Cobra. “The demands on our teams are intense and highly complex. Our ability to deliver safe, top-notch products relies on optimizing our systems for both productivity and reliability. We believe the new HP Universal Build Manager Powered by Dyndrite will meet our needs, help us push limits and set the standard across our entire additive manufacturing processes.”

Related Content

-

What Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.