GE Additive’s Amp Integrates Build Prep Tools in One Software Platform

The integrated software solution was developed to make it easier for users to develop and 3D print parts quickly and efficiently in order to speed production.

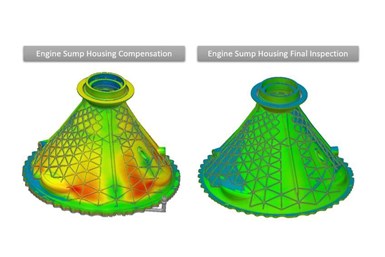

The company says using simulation-based compensation software reduced deformation by about 60% on the GE Catalyst sump housing. Photo Credit: GE Additive

GE Additive’s Amp is a cloud-based, process management software platform that puts additive manufacturing (AM) build preparation tools into one integrated software platform. The first two modules — Print Model and Simulation & Compensation — are now available in limited release for Concept Laser M2 machine users, with a wider release planned for the second quarter of 2022.

Amp is a result of GE Additive’s collaboration with GE Aviation and GE Global Research. The integrated software solution was developed to make it easier for users to develop and 3D print parts quickly and efficiently in order to speed production. According to the company, additive users can now move toward industrialization with a repeatable, consistent and streamlined process to scale and transform their business.

Amp was developed and designed exclusively for GE Additive machine customers. According to the company, the software integrates the tools engineers need to manage, process and manufacture metal additive parts on one integrated platform. From development to print production, Amp is said to offer a flexible, streamlined workflow so manufacturers can improve part production and significantly reduce trial and error needed to develop print-ready parts.

Amp is also designed to break down the silos between CAD, build prep, simulation, compensation and inspection data to help improve part production. With centralized data, users can access tools that simulate how the manufacturing process unfolds in real time and see the estimates for cost and time for a part throughout the process. Amp is said to streamline the process by using a single database that supports seamless data transition between tasks.

The company says that Amp incorporates GE’s industrial knowledge, best practices and workflows, and time/cost analyses. The software helps produce accurate simluations by closely tying Amp to GE Additive’s laser printers to start with precise information about printer parameters and capabilities. By combining this with GE’s knowledge of material properties, Amp can offer “recipes” that have been pre-populated with all the parameters users need to print the part, thereby enabling engineers to move through design and development faster.

Related Content

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

-

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.