Formlabs Launches Low-Force Stereolithography 3D Printers

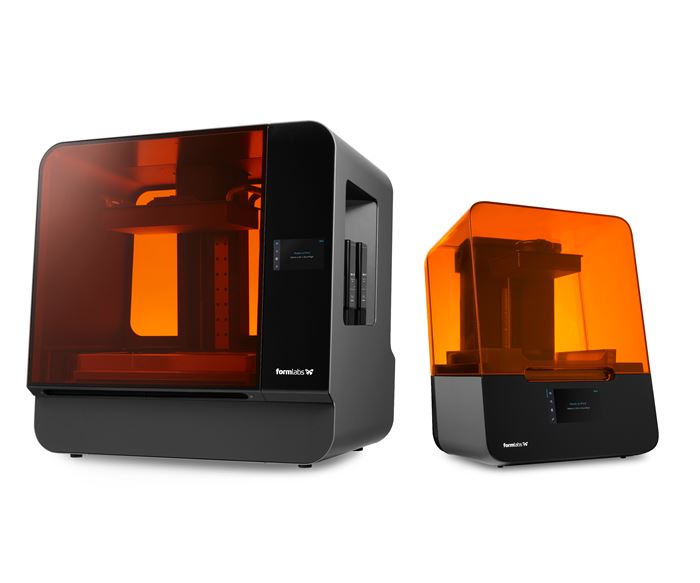

Formlabs has launched its Form 3 and Form 3L Low Force Stereolithography (LFS) printers, aiming to advance digital fabrication and further 3D printing technology.

Formlabs has announced the addition of the Form 3 and Form 3L, advanced professional Low Force Stereolithography (LFS) 3D printers. The LFS process uses a flexible tank to reduce the forces of the peel process, providing high-quality surface finish and detail, and linear illumination to deliver accurate, repeatable parts.

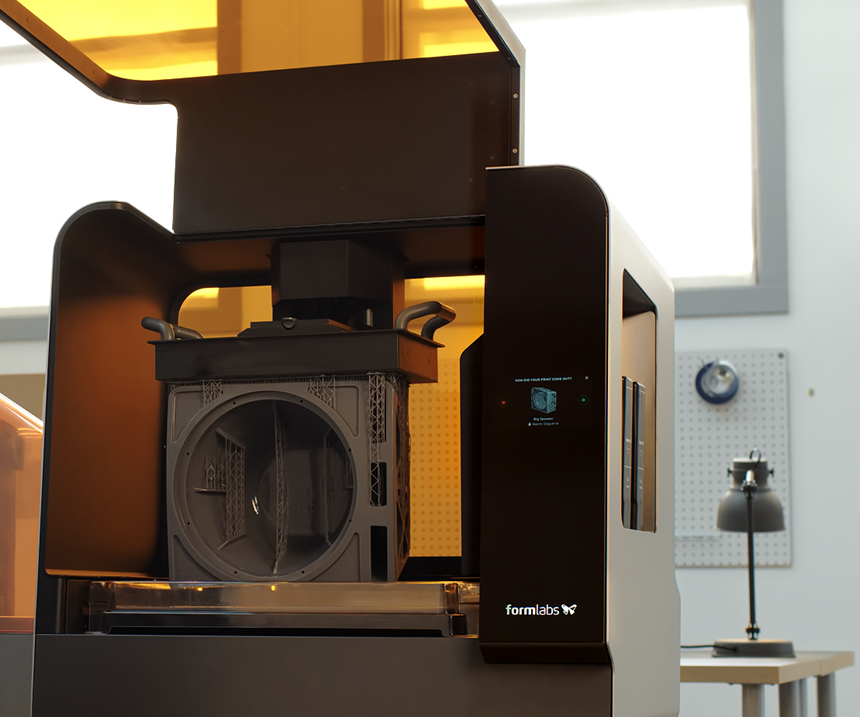

The LFS process offers improved detail and surface finish with its flexible tank that is said to reduce forces on parts while printing. Its Light Processing Unit (LPU) maintains a uniform, high-density laser spot for print precision and the technology provides tear-away light-touch supports for easier clean up and smoother parts. Integrated sensors maintain optimal print conditions and can send users alerts about the state of the machine. The printers are also said to provide constant uptime with upgradeable, modular components, the company says. Users can also remote 3D print from anywhere via the online dashboard.

“We’ve completely re-engineered our approach to resin 3D printing with the Low Force Stereolithography (LFS) print process behind the Form 3 and Form 3L,” says Max Lobovsky, CEO and co-founder of Formlabs. “Users are leading the way in how to grow 3D printing from one machine to many, from prototyping tool to game changer.”

“We're excited to take another huge leap forward with LFS 3D printing, improving the print quality and reliability people can expect while still offering a powerful and affordable 3D printer,” Lobovsky says.

The LFS print process behind the Form 3 is built to scale. The Form 3L simultaneously uses two Light Processing Units (LPUs) to support large-format 3D printing in-house, offering five times the build volume and two times the laser power of the Form 3.Related Content

-

Medical Molder Relies on 3D Printing to Speed Development of Inspection Fixtures

Medical molder Medbio uses FFF and SLA 3D printers in designing (and sometimes producing) its inspection fixtures.

-

Formlabs’ Form 4 3D Printer Offers New Levels of Reliability and Speed for Stereolithography

The Form 4 is designed to deliver most parts in less than two hours, offering users a powerful, affordable tool to bring ideas to life at fast speeds with excellent reliability, print quality and ease of use.

-

Fizik Utilizes Carbon DLS Technology for One-to-One Program, Creating Customized Bike Saddles

Fizik’s customized bike seat program uses Carbon’s Digital Light Synthesis technology and personalized rider data to create a line of truly custom saddles, giving bike riders the best bike seat for their posterior — only made possible through additive manufacturing.