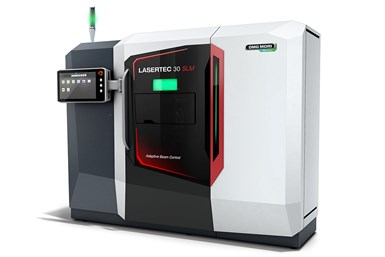

DMG MORI Develops, Manufactures Lasertec 30 SLM for US Market

The machine features several key advancements, including adaptive beam control which enables dynamic changes to laser power, laser speed and laser beam profile.

The Lasertec30 SLM US is being developed and manufactured at DMG MORI Manufacturing USA Inc. in Davis, California. Photo Credit: DMG MORI

DMG MORI has launched the domestic development and manufacturing of its Lasertec 30 SLM US, which features adaptive beam control, to address the rising demands of the U.S. market.

The Lasertec30 SLM US will start delivery December 2023. The machine is designed to offer best-in-class cost per part and complex geometries in an envelope of 11.8 × 11.8 × 11.8 in. The machine features several key advancements, including adaptive beam control which enables dynamic changes to laser power, laser speed and laser beam profile.

Noncontact recoating improves the freedom and independence of powder spreading. It offers best-in-industry production cost using an optional hybrid toolpath strategy that dynamically changes between laser beam profiles using a 1.2 kW laser, the company says.

With R&D and manufacturing for additive manufacturing (AM) in the U.S., Japan and Germany, DMG MORI aims to answer the growing demand for additive technologies in the U.S. market and abroad. All this contributes to the supply chain resilience and supports export-regulated applications or industries in local markets. The company says the Lasertec30 SLM US will be the first AM product to fulfill this requirement.

As a provider of machine tool manufacturing, DMG MORI has expanded its portfolio of conventional manufacturing methods with additive technologies since 2013. Its LasertecDED hybrid and LasertecSLM models enable highly productive and reliable manufacture of additive metal components within the holistic DMG MORI ecosystem, going from metal powder to high-precision finish machining.

In the Additive Intelligence consulting unit, DMG MORI also supports beginners and experienced users in fully exploiting the potential of metallic 3D printing. DMG MORI partners with customers for the next generation of manufacturing method through continuously developing innovative solutions in AM and metal processing.

The launch of the Lasertec30 SLM US coincides with the 40th anniversary year of DMG MORI USA. It marks another growth milestone for the company in the U.S. With 12 locations in the U.S. featuring technology centers, showrooms and the DMG MORI Manufacturing USA production facility in Davis, California,

DMG MORI has built up a regional presence in the country to support local customers. Further, it contributes to developing the skill set in the local workforce, which also serves the local communities.

- Read about DMG MORI working with Illinois Tech to establish National Center for Advanced Manufacturing in Chicago. The center will focus on workforce training for additive manufacturing and related advanced manufacturing industries.

- Learn about DMG MORI’s Hybrid 3D Printer which offers 5-axis simultaneous machining. The Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with 5-axis, turn-mill machining in one setup.

Related Content

-

Velo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

-

Big Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

-

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.