Carbon Releases Epoxy (EPX) 82 and Elastomeric Polyurethane (EPU) 41

Carbon’s Epoxy (EPX) 82 is a high-resolution and high-strength engineering material with long-term durability, and its Elastomeric Polyurethane (EPU) 41 is a production-scale elastomeric material offering higher resilience for making durable, elastic lattices.

Share

Read Next

Carbon’s Epoxy (EPX) 82 is a high-resolution and high-strength engineering material with long-term durability, and its Elastomeric Polyurethane (EPU) 41 is a production-scale elastomeric material offering higher resilience for making durable, elastic lattices.

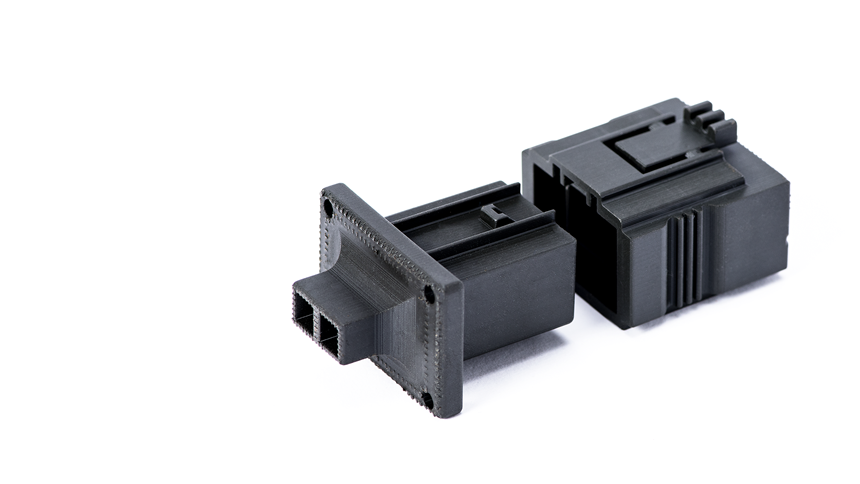

EPX 82 has a heat-deflection temperature of 125°C and good impact strength, making it useful for applications requiring a balance of strength, toughness and thermal-cycling durability. Example applications include connectors, brackets and housings in the automotive and industrial sectors. Its mechanical properties are comparable to lightly glass-filled thermoplastics and meet the USCAR-2 fluid compatibility standards.

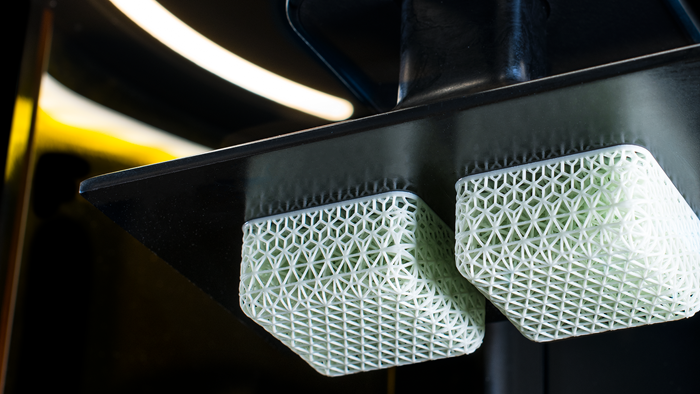

EPU 41 enables the production of elastomeric lattice geometries that can outperform traditional foams. It has higher resilience at room and low temperatures compared to EPU 40, and its tear strength, energy return and elongation facilitate cushioning, impact absorption and comfort. EPU 41 also performs well in functional testing, including fatigue, hydrolysis, UV-stability and plastic deformation tests, the company says.

Customers can use EPU 41 with Carbon’s tunable elastomer lattices and software tools to surpass previous benchmarks of comfort, safety and performance. Carbon’s software tools also eliminate the trial-and-error process of creating lattices, enabling designers and engineers to confirm they can be manufactured, test load requirements and create multiple functional zones within the same part.

Related Content

-

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.