B9 Elite Micro 3D Printer for Medical, Industrial Microscale Applications

The B9 Elite Micro offers ultrahigh resolution, accuracy, precision and repeatability, pushing the boundaries of feature size capabilities at the scale and tolerances nearly meeting or exceeding micro injection molded parts.

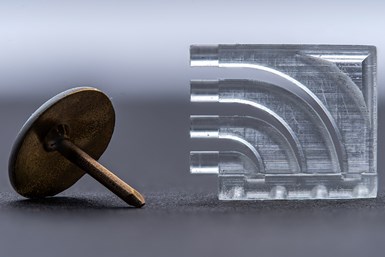

B9Creations’ ultraprecision B9 Elite Micro 3D printer platform delivers micro holes and thin wall thicknesses for parts, pushing the boundaries of feature size capabilities. It is said the printer enables users to 3D print geometries that would be impossible to create any other way, redefining additive’s place in the manufacturing ecosystem and fueling a new revolution spanning several medical and industrial applications.

The B9 Elite Micro offers ultrahigh resolution, accuracy, precision and repeatability, pushing the boundaries of feature size capabilities at the scale and tolerances, nearly meeting or exceeding micro injection molded parts. It offers native pixel size of 20 microns with microscale features such as wall thicknesses down to 30 microns and holes down to 100 microns, to deliver the most challenging micro parts at production quality.

The printer’s features include easy setup as it is out-of-the-box and printing in 15 minutes with factory startup assistance included and never requires recalibration. It also offers intelligent print preparation, management and monitoring software; and a streamlined workflow with automated cleaning and curing postprocessing units.

The system is open to B9Creations resins or third-party materials, or users can have B9Creations develop a custom resin. Its annual service package includes on-site training and installation, dedicated customer success specialist, hot swap program and more. The printer is also customizable by build volume, resolution and accuracy, materials, software, regulatory standards, application and even a B9 expert team.

- Read about B9Creations’ partnership with nanomaterial company Mechnano to expand its range of engineering photopolymer materials designed to take additive manufacturing into scaled production applications.

- Learn more about B9Creations’ customizable 3D printer platform, which is available in five configurations, all designed to deliver volume production and effective resolution.

Related Content

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.