Six Companies Aim to Revolutionize UK's Tool and Die Sector

The University of Strathclyde’s Advanced Forming Research Centre (AFRC) has joined forces with six other companies to revolutionize the UK’s tool and die sector.

The University of Strathclyde’s Advanced Forming Research Centre (AFRC) has joined forces with six other companies to revolutionize the UK’s tool and die sector. The two-year project, named DigiTool, is partly funded by Innovate UK and worth £1.2 million. Designed to combat the costs associated with die replacement and repair, the project seeks to extend lifespan and improve functional performance.

Project partners, all from the advanced manufacturing space, include Toolroom Technology Limited (TTL), Applied Tech Systems (ATS), Hybrid Manufacturing Technologies (HMT), InSphere and Kimber Mills International. They aim to provide organizations with the capability to remanufacture worn or damaged dies by helping them embrace additive manufacturing, adaptive machining and Industry 4.0.

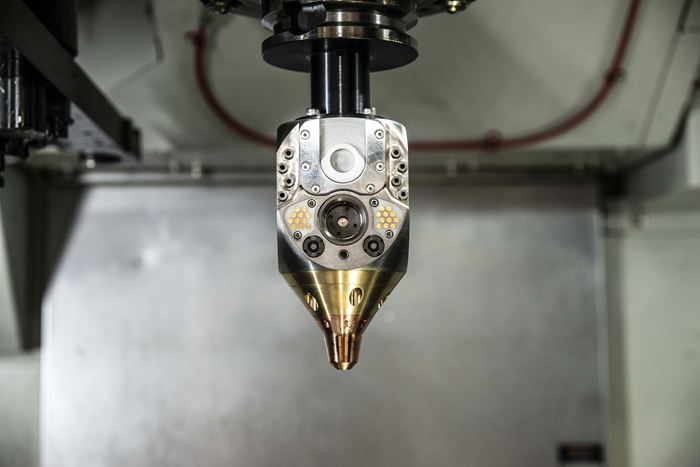

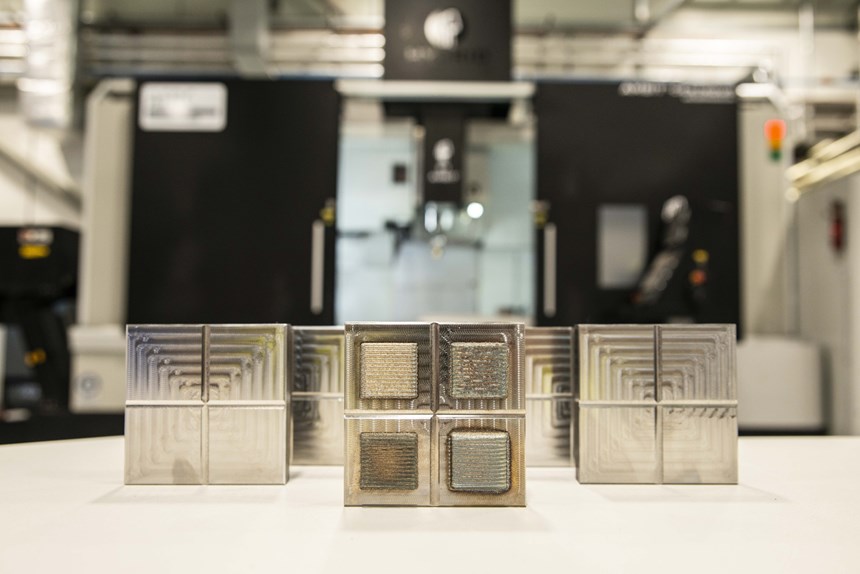

Using new technologies and processes to remanufacture worn dies instead of replacing them aims to help firms save on costs and materials while being sustainable. The consortium is exploring additive manufacturing and adaptive solutions for remanufacturing damaged areas on dies using a retrofitted legacy machine tool. Scanning and metrology is used to discover worn areas before employing additive manufacturing techniques, such as laser metal deposition, to complete the remanufacture back to the desired die form.

Designed for easy integration within one digital platform, the DigiTool framework aims to provide an affordable solution for SMEs looking to adopt new technologies without purchasing a new machine.

Toolroom Technology Limited (TTL) is leading the project. The AFRC is heading up all areas of additive manufacturing, while the other partners are delivering research on their respective areas of expertise, including metrology and scanning, adaptive machining, and digital integration. The new manufacturing methods will be combined on one platform at AFRC, using its recently installed LMD Hybrid Machine, which integrates additive manufacturing with machining. Initial project trials have already been carried out and the partners are currently analyzing a die for a railway application from Kimber Mills and plan to remanufacture and bring worn dies back into service.