Purdue Researchers Add Fourth Dimension to 3D Printing

Researchers say that with the sensors dispersed evenly in the filament, manufacturers and researchers can design parts with a wider variety of shapes.

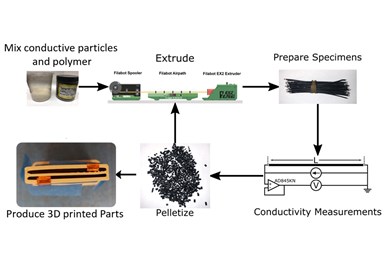

Purdue University researchers have developed a wet-mixing method to add sensor particles to 3D printer filaments, which will enable manufacturers to create functional printed parts. Photo Credit: Purdue University image/Brittany Newell

Purdue University researchers have developed a method for adding particles to filament and evenly dispersing them through a traditional fused deposition modeling (FDM) 3D printer, which they say will aid the industry in manufacturing functional parts.

Brittany Newell and Jose M. Garcia-Bravo, associate professors in the School of Engineering Technology in the Purdue Polytechnic Institute, and Tyler Tallman, assistant professor in the School of Aeronautics and Astronautics in the College of Engineering, have created a wet-mixing method to introduce electrically conductive particles into 3D printing filament polymers. Cole Maynard, who earned his doctorate, and Julio Hernandez, a doctoral candidate, were also pivotal to the research.

Traditional 3D printing makes prototypes of parts with no sensing capabilities. Sensors must be added to the part after the fact if assessments are to be made. The process can be thought of as adding sprinkles to cookies after they are baked: The sprinkles exist only on the outside of the cookie. Traditional foil-type strain gauges, which are the most common strain sensors, are adhered to the surface of a printed part by an epoxy resin, Newell says.

However, in this work the sprinkles are added throughout the cookie dough before baking. This means that sensing capabilities are an inherent part of the printed component and enable sensing inside the component. Unlike sprinkles, these sensors are too small to be seen without a microscope. Their tiny scale enables the printed part to maintain strength it would have otherwise sacrificed due to large sensors built in, while still achieving fully integrated sensing capabilities.

“Generally, we apply that strain gauge across the full part or apply it to the top and bottom of the part to get information on overall strain across the part,” Newell says. “However, the middle and internal structures are never monitored since the gauges are glued to the surface.”

It is said the Purdue wet-mixing method ensures an even distribution of particles throughout the filament. With the sensors dispersed evenly in the filament, manufacturers and researchers can design parts with a wider variety of shapes.

“The results from this work enable users to create complex 3D structures with embedded strain gauges, rapidly moving traditional prototype pieces into fully functional and structurally assessable parts,” Newell adds. “A limitation of application of 3D printed parts has been in their durability. With this development, we can continually monitor the structural health of the part with the sensor embedded in the print.”

This method produces materials that are conductive with very good uniformity, which greatly expands the electrical applications of 3D printed parts and sensor designs. Also, the materials are tunable, which means that manufacturers can adjust the electrical and mechanical properties to optimize the sensor or part for a desired application.

However, the wet-mixing process is not limited only to sensor conductivity. “This work can be further expanded to add other particle types using the same wet-mixing method,” Newell says. “This could include the addition of magnetic particles for electromagnetic fields, fluorescent particles and other functionalities.”

Newell said industry partners are being sought to create a process to scale up and further test the method. “We need to increase the batch size to an industrial scale and integrate the customizable aspect of this work with industrial 3D printers,” Newell adds. “The range of items that can be produced with these filaments is broad, and testing should be done to expand to new prototypes.”

- Learn how 9T Labs and Purdue have collaborated to advance composite use in structural aerospace applications.

- Read about the Matsuura-Purdue partnership which is working to advance innovations in convergent manufacturing with researchers converging an array of processes in one platform to enable breakthroughs in manufacturing science and engineering.

- In another collaboration, Purdue University established a large-scale Thermwood LSAM Research Laboratory to perform industry-funded research into large-scale composite thermoplastic AM.

- Listen to Episode 38 of The Cool Parts Show to learn how magnets have been printed successfully at the Oak Ridge National Lab, and the implications this has for energy, material conservation and supply chains.

Related Content

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreA Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More