Protect and Ensure: Graduate Course Teaches Preparedness in Additive Manufacturing Legal Issues

A Graduate course at Penn State University aims to prepare students to be thought leaders and technical experts by exploring intellectual property implications in additive manufacturing.

Share

Read Next

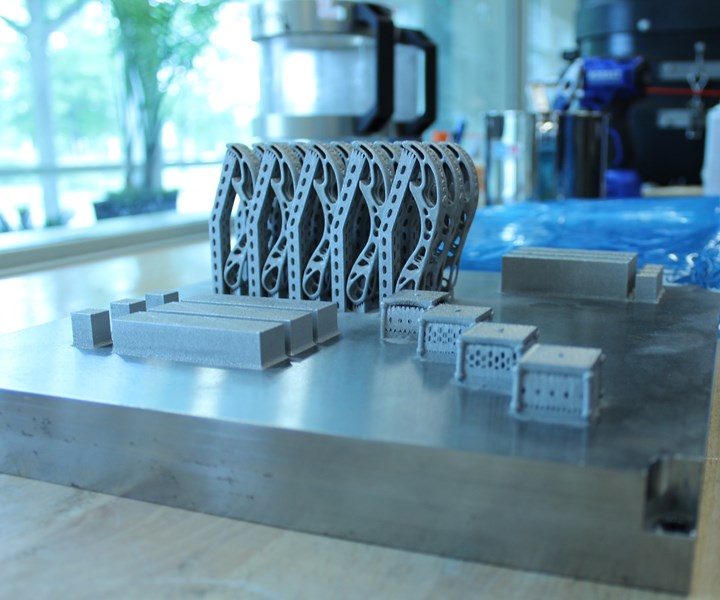

A while back, Additive Manufacturing Media launched a series covering the Additive Manufacturing Master’s program at Penn State University. Combining classroom learning with hands-on experience through the design, 3D printing and postprocessing of a metal part (like this build plate), PSU emphasizes the underlying principles of AM.

When you have the freedom to create anything, how do you protect your design? In tandem, how do you ensure you are not violating an existing intellectual property? In the additive manufacturing (AM) industry, these concerns are intensifying and evolving. To prepare the industry’s next trailblazers, a new course in the Penn State Additive Manufacturing and Design (AMD) graduate program is seeking to address these legal concerns head-on.

“Additive manufacturing is disrupting product design and how we manufacture parts,” says Timothy W. Simpson, Paul Morrow Professor of Engineering Design and Manufacturing and director of the AMD program. “It’s also disrupting how we protect our intellectual property. Most engineers are not prepared to think about the impact this will have on how their company will deliver new products and services with AM.”

The AMD curriculum seeks to embolden students to become both technical experts and emerging thought leaders in the industry. Through the newly offered course — AMD 597 Legal Issues in Additive Manufacturing, the first of its kind in any AM curriculum, according to Simpson — students will have the knowledge necessary to help them navigate the legal issues arising in the AM field.

“Additive manufacturing is creating new ethical dilemmas that companies have to wrestle with," Simpson says. "Therefore, we have to prepare our AMD students for those challenges, especially when they take on leadership roles within companies seeking to exploit AM.”

Additive Manufacturing gives organizations the “freedom to create anything” and a recent video with Penn State University Professor Timothy Simpson covers the freedom of design and part orientation when building parts.

At its core, the AMD program draws strength from its interdisciplinary connections. It integrates graduate coursework across multiple departments, including mechanical engineering, industrial and manufacturing engineering, engineering science and mechanics, materials science and engineering, and the school of engineering design, technology and professional programs, as well as across the colleges of engineering and earth and mineral sciences.

With the new course offering, taught for the first time in summer 2019 by Daniel R. Cahoy, professor of business law, the program fuses new interdisciplinary collaborations with Penn State Law and the Smeal College of Business. Students who complete the course will:

- Know the fundamentals of creating valid legal contracts and be able to engage in secrecy agreements and licensing.

- Understand how patents and trade secrets support innovation in additive manufacturing and be able to interpret patent claims and documents.

- Know how to incorporate product liability law into the design of products and processes.

- Be able to create enforceable trademarks and understand how to form a valuable brand.

- Understand how copyrights and design patents protect creative content in additive manufacturing.

- Be able to identify obligations to apply cybersecurity and protect privacy rights.

Traditionally, engineers didn’t need to be well versed in the complex legalities of contracts, nondisclosure agreements and intellectual property, but Simpson explains that "the implications of additive manufacturing require them to carefully consider intellectual property in every aspect of their business models. This course demystifies the legalese and how additive manufacturing is changing the traditional paradigms to protect our intellectual property.”

Brenna McCornac, a student currently enrolled in the course and an additive manufacturing engineer at Cumberland Additive, agrees.

“As a working engineer, I feel that this is a valuable knowledge base to have. I don't believe that many engineers have the opportunity to learn a lot about the law, especially within their specific field,” McCornac says. “Those of us participating in this class will be uniquely equipped to work effectively in a corporate setting or start their own business, having a good basis of legal knowledge pertaining to additive manufacturing.”

As an elective as part of a master’s degree program, the course will help students gain valuable insight into how these issues are directly affecting industry. Christopher Higgins, partner and co-leader of the 3D Printing Group at the law firm Orrick, Herrington & Sutcliffe LLP, helped Cahoy develop and teach the course.

A practicing lawyer, Higgins has been grappling with the implications of AM in precedent-setting intellectual property cases for more than five years through the 3D printing and additive manufacturing division he co-founded at his firm.

He explained that as the industry continues to evolve, the graduates of this course will be poised to make a discernible impact.

“Legal issues, especially intellectual property, are at the forefront of many additive manufacturing companies’ concerns,” Higgins says. “As an engineer, having an understanding of legal issues that may arise in additive manufacturing can make you an invaluable asset to a company. It is a skill set that most engineers do not have when exiting school, which makes this course a unique opportunity at Penn State.”

For more information, email AMDProgram@psu.edu.

Editor’s Note: This article originally appeared here. Thanks to Penn State for allowing us to share.

Related Content

Free AMJobs Digital Tool Supports Additive Manufacturing Education, Workforce Development

America Makes’ AMJobs is a free digital tool that facilitates access to careers, supports industry growth and talent development in the additive manufacturing industry.

Read MoreGuha Manogharan Named Co-Director of Penn State’s Additive Manufacturing Center

Penn State’s Center for Innovative Materials Processing through Direct Digital Deposition is an interdisciplinary research center that works to advance additive manufacturing and materials research.

Read MoreEOS Additive Minds Academy Opens Space for Hands-On AM Training

The engineering, consulting and education arm of EOS has offered training in various capacities before now, but a new physical footprint at the company’s Novi, Michigan, facility will make AM training more accessible and affordable.

Read MoreCarnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More