Formnext 2023 Partners With Nordic Region Partners

The Nordic contingent will be based at the Nordic pavilion, where a special showcase of exhibits of successful AM applications is planned. Companies from the partner region will be presenting inspiring AM use cases, and the Danish AM Hub will be hosting a panel on sustainability.

The partner country for Formnext 2023 will play an important role in the event, which is scheduled for Nov. 7-10, 2023, in Frankfurt, Germany. The Nordic region, comprising the countries Denmark, Finland, Norway and Sweden, will have innovative companies participating at the event and play a significant role in the supporting events program.

At the exhibition, the partner region will be showcasing the economic potential of the Northern European additive manufacturing industry as well as shining a spotlight on sustainability — with a particular focus on energy and material efficiency. The lead partner, Danish AM Hub, will be joined by the Finnish Additive Manufacturing Ecosystem (FAME) and Norwegian AM, the additive manufacturing cluster for Norway.

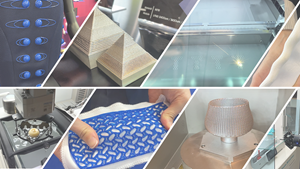

Approximately 660 exhibitors have already registered for Formnext 2023, which looks set to be a record year for exhibitor numbers. Joining them will be around two dozen exhibitors from the Nordic countries, which will be based at the Nordic pavilion, where a special showcase of exhibits of successful AM applications is planned.

As part of the program of supporting events, major companies from the partner region will be presenting inspiring AM use cases, and the Danish AM Hub will be hosting a panel on sustainability. Several delegations from the Nordic region are also planning to visit Formnext 2023 to further promote the industrial application of AM through active exchange and expansion of their networks.

“The Nordic region represents the ideal choice of partners for this year’s event as the countries concerned are showing the world how to combine commercial viability with sustainability, and thus perfectly demonstrating how 3D Printing can play its part in establishing a responsible manufacturing industry,” says Sascha F. Wenzler, vice president Formnext at event organizer Mesago Messe Frankfurt.

The Danish companies will showcase a range of innovations along the entire AM process chain, including research and development, services, materials and postprocessing solutions. For example, the young company Create it Real has developed a specialized solution for the orthopedics industry. Denmark also has a number of well-known companies that have been using 3D Printing for many years. Global enterprises, such as Lego, Danfoss or Grundfos, for example, are key users of AM.

The Finnish AM industry has strong links with the industry and will be bringing service providers (3D Formtech, 3DStep, Delva), software suppliers, polymer 3D printer manufacturers and companies from the research and development sector to Formnext. Sweden has long boasted a successful raw materials industry, and this is also reflected in the AM world with world-leading AM material manufacturers such as Sandvik and Höganäs. There will also be Swedish exhibitors from the entire process chain, presenting solutions for research & development, software, hardware, services and postprocessing.

As part of the Nordic partner region, Frank Rosengreen Lorenzen, CEO of the Danish AM Hub, welcomed the “recognition of the skilled and innovative Danish owner-managers, designers, engineers and manufacturers, who are continually challenging and expanding the scope of AM technology to design, develop and manufacture the products of the future.” Lorenzen also noted that, over the past three years, the Danish AM Hub has focused on “how to make Denmark the most knowledgeable place in the world when it comes to the use of AM for more sustainable manufacturing.”

A background to the AM industry in the Nordic partner region will be presented exclusively in a special edition of Formnext magazine, published at the end of August. Offering an additional preview of the exhibition will be Formnext’s appearance at the AM Summit Copenhagen, which will be taking place on Sept. 21, 2023.

- Learn about the 5 Big Themes in Additive Manufacturing at Formnext Forum: Austin. This two-day event is focused on additive manufacturing for production and includes a conference exploring important ideas in AM related to supply chains, bridge production, enterprise transformation and more.

Related Content

10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreMoldJet Technology Enables High-Throughput Metal, Ceramic Additive Manufacturing

Formnext 2023: Tritone Technologies’ additive manufacturing solutions enable industrial throughput of accurate parts with a range of metal and ceramic materials.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More