DSM 3D Printing Acceleration Program Accepting Applications

The I AM Tomorrow Challenge is a ten-week program designed to help startup companies launch or mature their additive manufacturing innovations.

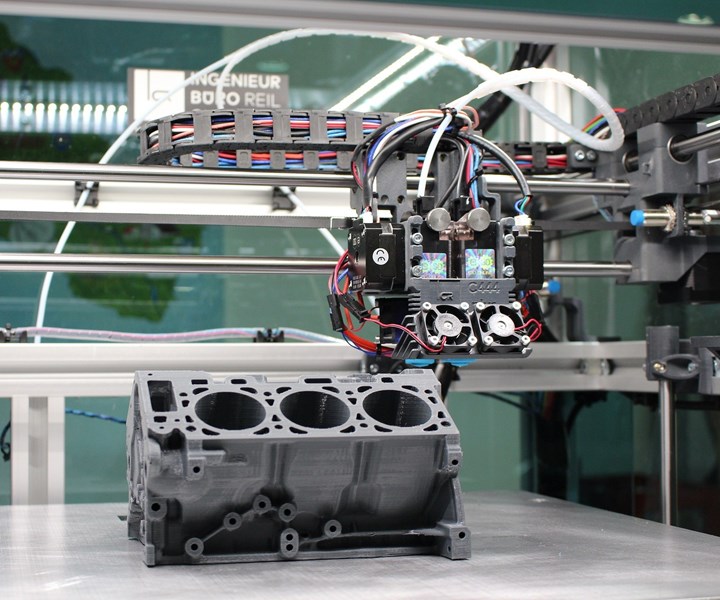

Royal DSM’s I AM Tomorrow Challenge focuses on data analytics, artificial intelligence (AI) and other software solutions for large-scale additive manufacturing.

Royal DSM recently announced the launch of its I AM Tomorrow Challenge, an acceleration program for startups and scaleups focused on data analytics, artificial intelligence (AI) and other advanced software solutions for large-scale 3D printing. Launched in collaboration with HighTechXL , Hexagon, and Ultimaker, the challenge offers select companies a spot in a ten-week acceleration program designed to launch or mature their businesses. After the acceleration program, participating startups may be eligible for funding or a partnership with DSM.

Startups and scaleups are encouraged to apply through August 8, 2019, at no cost. Ten successful applicants will be invited to participate in the acceleration program, located at HighTechXL’s campus in Eindhoven, as well as in Boston, Massachusets. The program will consist of expert coaching sessions, master classes and exclusive networking opportunities, the companies say.

During the program, Hexagon’s Manufacturing Intelligence division will work with DSM and partners to evaluate interested companies and work towards the development of a platform to provide end-to-end digital solutions for additive manufacturing.

“By building an ecosystem of partners, we can work together to create tools that support 3D printing design and production, helping our affiliates and customers create innovative new products in a more sustainable way,” says Hugo da Silva, VP of additive manufacturing at DSM.

SM says that its Somos products helped pioneer the additive manufacturing industry more than 25 years ago, and that the company is now actively collaborating with partner companies across the 3D printing value chain to unlock additive manufacturing’s full potential. The company says the I AM Tomorrow Challenge aims to stimulate the digital ecosystem that could shape the future of the industry.

Related Content

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

-

Researchers Develop Resin for 3D Printing Implants for Cataracts, Other Eye Conditions

The ability to 3D print intraocular devices for treating cataracts and other eye conditions could significantly enhance eye care for patients by offering unparalleled levels of customization and design precision, potentially leading to better clinical outcomes.

-

3D Printed Capo for Banjo Made With Binder Jetting not MIM: The Cool Parts Show #74

New market, no mold tooling needed: Additive manufacturing via binder jetting enables a maker of guitar capos to expand to serve banjo players as well.