Desktop Metal Completes Acquisition of ExOne

ExOne will continue to operate as a wholly owned subsidiary of Desktop Metal and will remain headquartered in North Huntingdon, Pennsylvania.

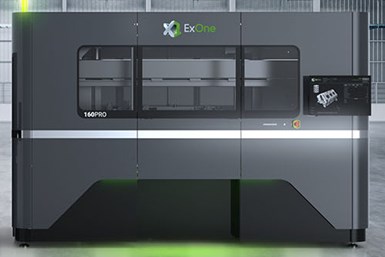

The X1 160Pro is ExOne’s largest and 10th metal 3D printer.

Desktop Metal has successfully completed its acquisition of the ExOne company following approval by a majority of ExOne’s shareholders. The acquisition brings together two additive manufacturing (AM) pioneers and complementary technology platforms for mass production.

ExOne extends Desktop Metal’s product platforms with complementary solutions that are said to create an AM portfolio that offers industry-leading throughput, flexibility and materials breadth, providing customers with a variety of options to address their specific applications.

Desktop Metal says it is committed to supporting ExOne’s existing customers around the world, as well as leveraging its global distribution network alongside ExOne’s direct sales force to provide businesses of all sizes with broader access to its AM 2.0 solutions and expanding materials library.

“This acquisition is a landmark moment for the additive manufacturing industry and creates an unmatched portfolio that strengthens Desktop Metal’s ability to accelerate the adoption of AM 2.0,” says Ric Fulop, Desktop Metal founder and CEO. “We are proud to welcome ExOne’s talented team to Desktop Metal and to move forward as one company focused on the mass production of end-use parts through AM. We’ve begun the process of careful integration with the goal of driving outsized growth for the combined company in the years to come. We believe Desktop Metal is uniquely positioned to provide the widest range of end-use applications, and we are excited about the value creation opportunity for our customers, partners, shareholders and employees."

ExOne will continue to operate as a wholly owned subsidiary of Desktop Metal and will remain headquartered in North Huntingdon, Pennsylvania.

Related Content

-

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.