BigRep Expands Printing Services with 3D PARTLAB

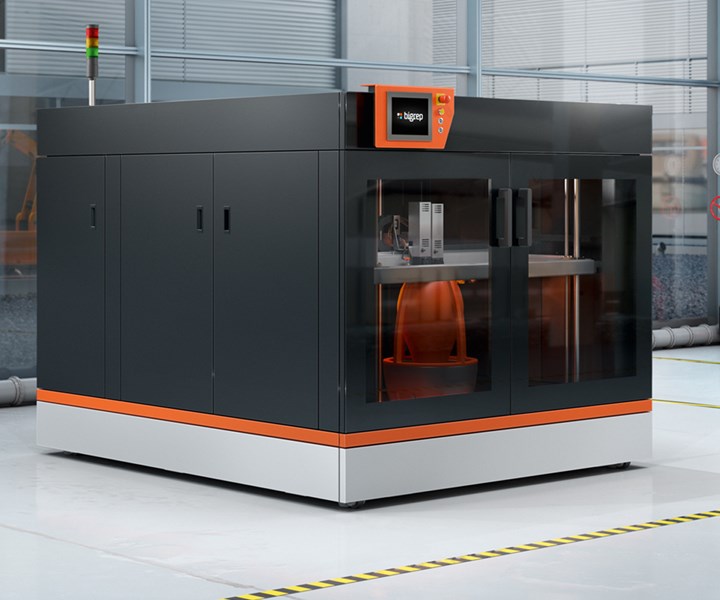

BigRep America is opening a new headquarters featuring the new BigRep 3D PARTLAB for flexible 3D printing services with its fleet of large-format 3D printers.

Share

Read Next

BigRep.

BigRep has announced the expansion of its product offering to include 3D printing services for new and existing customers in North America. The new BigRep 3D PARTLAB will be located in BigRep’s new American headquarters in Boston, Massachusets.

“Addressing a growing demand in the market for flexible AM printing services, BigRep 3D PARTLAB will set a new standard in customer services for both existing and new industrial clients looking for innovative AM solutions from proven professionals,” says Frank Marangell, BigRep CBO and President of BigRep America. “PARTLAB will support both our partners and customers who are over capacity and assist other companies in need of large-format parts printed by industry experts.”

BigRep 3D PARTLAB will offer customized ordering services for 3D printed parts including prototypes, tooling, molds and even end-use parts; printed to the customers’ specifications with BigRep’s extensive line of engineering-grade materials. PARTLAB is expected to make the full potential of the company’s technology and expertise in large-format additive available to new customers while offering comprehensive services for BigRep’s industrial customer base across North America.

Related Content

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

-

Part Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.