BASF Ultrafuse 316L Stainless Steel Qualified for MakerBot Method 3D Printers

Users can explore printing rigid 316L stainless steel parts for industrial applications alongside advanced engineering polymers and composites on Method with the MakerBot Labs Experimental Extruder.

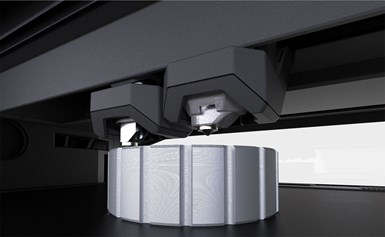

MakerBot extruders printing metal.

MakerBot, a Stratasys company, announced that the BASF Ultrafuse 316L Stainless Steel material by Forward AM has been qualified for the MakerBot LABS Experimental Extruder for MakerBot Method 3D printers. The Method industrial desktop 3D printer has an open materials platform and a heated chamber that can print polymer, composite and metal materials.

The company says the Ultrafuse 316L Stainless Steel material combines high strength, rigidity and durability needed for a range of applications, including functional prototypes and manufacturing tools. Available using the MakerBot Labs Gen 2 Experimental Extruder, this metal-polymer composite material provides users with an accessible and cost-effective option to experiment with metal 3D printing applications.

3D printing stainless steel parts can shorten the time it takes to produce parts, further reducing operational costs compared to traditional methods, the company says. Method’s heated chamber and ability to control the speed at which a part cools down during the printing process can also help reduce the risk of delamination.

Once the part is printed with BASF Forward AM Ultrafuse 316L, it can be sent out to postprocessing or specialized manufacturing facilities for debinding and sintering, which turns the part printed with the composite material into solid stainless steel. This process enables users to create stainless steel parts without investing in expensive debinding and sintering equipment. Final parts can achieve up to 96% of the density of pure 316L metal material, enabling users to produce lightweight, hollow metal parts with high tensile strength compared to polymers that would be difficult to produce in other ways.

Ultrafuse 316L material properties make it well suited for a variety of manufacturing tools, jigs and fixtures and end-use parts, such as workholdings that need to withstand high temperatures; brackets that require high strength and custom designs for specialty machinery; or robotic grippers that need to be strong, lightweight and wear resistant.

Related Content

-

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

-

To Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

-

3D Printed Human-Operated End-of-Arm Tooling Promotes Safety and Throughput

Toolmaker and injection molder Zero Tolerance developed a manual tool to enable an operator to quickly place inserts into a mold.